FORWARD FOODING

THE BLOG

Why fungi fermentation is a blooming innovation

Fermentation is rapidly becoming a buzzword within Foodtech, gaining increasing recognition as a groundbreaking enabling technology to replace everyday foods with more sustainable alternatives. This incredibly old process goes back to as early as 7000 B.C. in China, with evidence suggesting that humans were already using it for beverages. But for how ancient and widespread it may be, not many of us are familiar with all its nuances and market products available to us thanks to it.

So, let’s take a closer look at it.

The basics: what is fermentation?

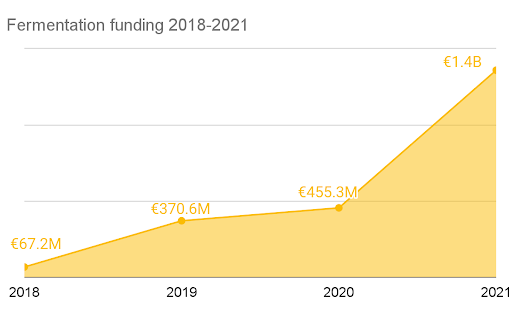

Generally, fermentation can be described as the process of altering some food characteristics thanks to microbial activity. According to our FoodTech Data Navigator, fermentation, one of the three pillars of alternative protein alongside plant-based and cellular agriculture, was the second most funded technology in 2021 alone. Indeed, it accounted for over 30% of capital raised in the whole alternative protein sector, equal to over €1.4B. Such an amount is not surprising, as companies working on fermentation on average have more than doubled their funding each year since 2018, at a CAGR of 173% between 2018 and 2021. Without going into too much detail regarding each fermentation type (which you can find here in our deep dive into the whole alternative protein space), we can generally recognize three main kinds of fermentation: traditional, biomass and precision.

Source: FoodTech Data Navigator

Why fungi fermentation is different?

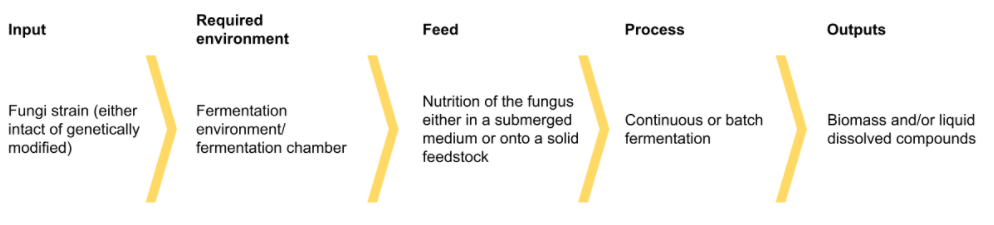

What defines fungi fermentation, as the name suggests, is the fact that a fungus (the kingdom where mushrooms belong to) is grown into a chamber, called a fermentation tank, and onto a surface used for feed, called substrate. By fermenting the fungus, the time needed for the development of the organism is reduced drastically and hence suitable for industrial use.

Even for those familiar with FoodTech terminology, this may seem a new term as fungi-based fermentation is generally labeled as “biomass”. This is due to the fact that Quorn, who paved the way for this technology back in the 1980s, used the fungi’s biomass, the resulting body of the microorganism and high in protein content, as the only output. The term “Mycoprotein” was eventually coined by the company to indicate that its products were in fact made with the fungi’s biomass. This has long been the only output harvested from the process. However, recent tech developments make it now possible to obtain a wider array of products from fungi fermentation.

Technical details

There are of course nuances to this process. The substrate can be in a liquid or solid form. In the former, the fermentation is called “submerged fermentation” and normally allows for a quicker production cycle, while the latter is called “solid-state fermentation” and generally presents a slower production turnaround.

Another difference is represented by the production cycle itself, which can be in batches (hence ending the cycle after the harvest of the output) or continuous (where the cycle doesn’t stop after the output harvest but more feed is introduced to continue it, although careful overseeing is required). While traditionally companies active in fungi fermentation have been resorting to the batch technique, and even most promising ones like MycoTechnology are doing so, this method allows for only limited economies of scale given to technology constraints (at the time of writing). On the other hand, ENOUGH is leveraging continuous fermentation despite working with fungi, therefore leveraging a more efficient production cycle and use of inputs.

Old and new applications

As mentioned in previous sections, fungi fermentation has been long associated with biomass fermentation and therefore used only as an alternative source of proteins, initially by Quorn and more recently by many others.

However, thanks to the hybridization of techniques and methods, fungi fermentation now is becoming an ever-popular alternative attracting great capital. Evidence of this can be found in ENOUGH raising a $51M (€42M) series B back in June or MycoTechnology a $39M series D in June 2020 and Nature’s Fynd’s whopping $350M series C from July last year.

The latter has been busy at work using its special fungi strain to develop a new mycoprotein called Fy. This has enabled Nature’s Fynd to bring to the market a fungi-based sausage patty and the first-ever cream cheese made via this method, This latest funding round is fuelling the company’s efforts to increase production in order to hit mass-retail in US and Asia geographies within the current year also thanks to planned manufacturing facilities in Singapore and Chicago currently under construction.

Nature’s Fynd cream cheese

MycoTechnology is also at the forefront of novel applications for this technology thanks to its new way of approaching submerged fungi fermentation. Their technology allows the production of ingredients that can be used as sugar alternatives, alternative proteins and natural additives, available for use in plant-based products to improve the mouthful experience. The company is able to achieve such a diverse array of products by leveraging both the resulting biomass and the liquid-dissolved compounds. MycoTechnology also has an ongoing partnership with Planterra, part of OZO (JBS plant-based brand) specifically to use fungi in order to elevate the plant-based experience.

Some of MycoTechnology’s lineup

The Swedish Mycorena has also made headlines after it managed to make fat analogs using fungi fermentation, effectively paving the way to fungi becoming a staple ingredient in meat alternatives. Companies to the likes of Impossible and Beyond, which target meat-eaters too, could soon start implementing such ingredients in their future product lineup. In fact, Mycorena is already opening to B2B opportunities aiming at elevating the mouthfeel of plant-based products with this novel ingredient.

Fungi-based fat analog by Mycorena

Finally, we mentioned how hybridization is playing an increasingly important role in what fungi fermentation is capable of. That is the case for Michroma in Argentina and Chromologics in Denmark, who are leveraging biotechnology in the form of precision fermentation applied to fungi, genetically modifying them. The result for both is that they effectively have been able to synthesize natural colorants for the food industry from fungi, which is something that was inconceivable just a couple of years ago. Both companies are now actively looking for commercial partners while seeking regulatory approval in the US and Europe to speed up their go-to-market strategy

What is ahead of us?

Given how fast the whole FoodTech space is moving and in particular the fermentation technologies, it’s challenging to foresee what is coming our way next. It is likely that companies will follow one of two main paths in future product development.

On the one hand, precision fermentation (which can theoretically allow synthesizing all molecules needed in the food industry by providing genetic instructions to the microbes) applied to fungi will see more newcomers enter the space given such versatility of outputs.

However, this will pose some challenges due to GMO regulation imposed by many countries and that companies working with genetically modified fungi would be subjected to.

On the other hand, specialty ingredients beyond proteins but made without the use of GMO fungi, as proven by MycoTechnology and Mycorena, are achievable and will draw much more attention due to their market readiness and potentially lower production cost.

Do you want to learn more about the alternative protein space, the challenges that the sector is facing and the opportunities you can harness? Access our Food Data Navigator HERE to discover all the companies working in this sector, or get in touch HERE for a tailored consultancy.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]