FORWARD FOODING

THE BLOG

From Waste to Taste: The Bone Upcycling Journey of SuperGround

Santtu Vekkeli’s passion for sustainability and flavour collided with his entrepreneurial spirit and founded SuperGround. In a world where upcycling often focuses on agricultural goods, SuperGround takes a bold step by turning overlooked bones into tasty and nutritious sidestream products.

We interviewed food scientist, microbiologist, and entrepreneur, Santtu Vekkeli, the visionary behind SuperGround and one of the finalists for this year’s FoodTech 500. The upcycling company also participated in this year’s FoodTech 500 Lab at Sweden FoodTech’s Big Meet Conference.

Rather than viewing bones as mere waste, Santtu recognized an opportunity and developed the technology that transforms fish and poultry bones into products that create a symphony of taste and nutrition.

SuperGround Founder, Santtu Vekkeli

SuperGround Founder, Santtu Vekkeli

Bone Consumption Beyond Tradition

Bone consumption has a rich history across various cultures. From hearty broths to flavorful stews, bones have long been valued for their nutritional benefits. Consider small fish like mackerel—often consumed whole, bones and all. Bones are packed with nutrients and contain protein, water, fats, and minerals.

However, as consumer preferences evolve, the food industry has adapted. In the food industry, bones are often seen as a biting hazard. Many fish and poultry products are now deboned before reaching our plates. As Santtu points out, the reason for the avoidance of bones are more psychological than technological. This shift leaves companies with surplus bones, posing a disposal challenge. In the fish processing industry, up to 70% of the total fish weight is discarded for fish fillets and related products.

Image courtesy of SuperGround

But this led us to a situation where the bones are collected at one point of the whole food chain instead of the consumer level. In fact, the fish industry is very keen on finding solutions to their sidestream problem and upcycling bones can potentially address this.

SuperGround has developed and patented mechanical processes to upcycle poultry and fish bones using existing machines in the food industry, while making sure that the process they create have significantly lower emissions than conventional processing. For Santtu, there’s been such a cultural change in how consumers perceive bones and it’s a challenge to make consumers change their consumption patterns. So his way is to sneak upcycled bones back into people’s diets.

This interview has been edited for clarity and concision.

Forward Fooding: What was your story behind starting SuperGround?

Santtu: I have listed problems in the global food system for over a decade. One of the biggest problems is food waste and how to tackle the large-scale utilisation of bones as tasty food.

I had my ‘aha moment’ a few years ago and understood that bone upcycling might be a solution by combining and modifying existing food processing machinery. I discussed this with a few investors, which was SuperGround’s start.

FF: What are the potential benefits of incorporating SuperGround technology into meat and fish products?

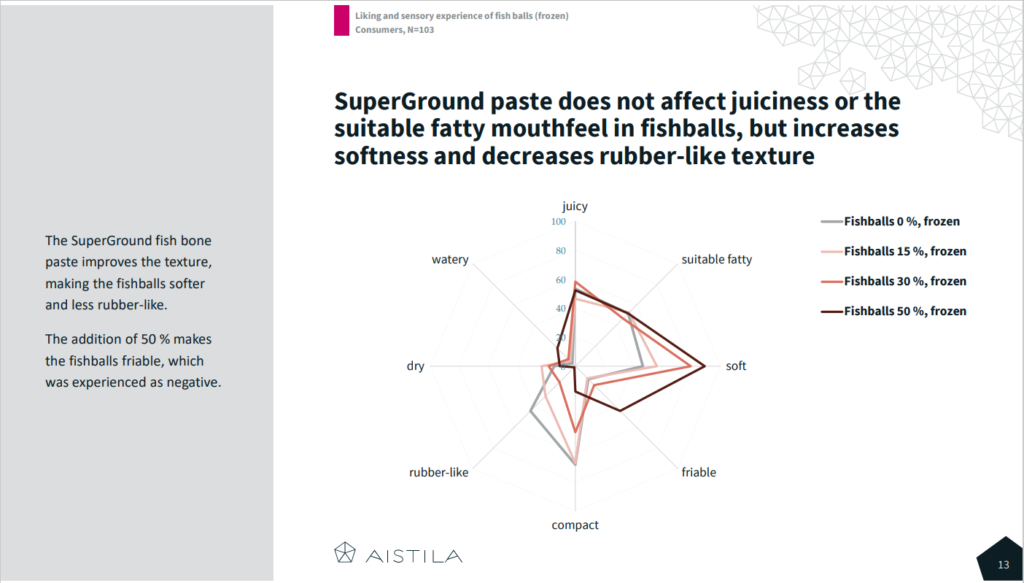

Santtu: SuperGround paste can improve the flavour profile of the product. According to research done by Aistila (which is a sensory laboratory in Turku, Finland), the SuperGround paste improves the “meaty taste” and “taste” profiles of chicken nuggets.

SuperGround paste also improves the nutritional value of the product by diversifying its nutritional content. Adding SuperGround paste to the product can increase its calcium and mineral content. It also has different concentrations of fats and vitamins compared to muscle tissues alone.

FF: Can you provide more details about incorporating SuperGround paste into your meat products? How does the percentage of SuperGround paste added affect the sensory attributes of the fish balls and nuggets, such as odour, appearance, taste, and texture?

Santtu: In some products, such as Nordic rainbow trout balls or patties, the paste can be added to up to 30% of the product without a perceptible change in sensory properties for the consumer compared to a product without SuperGround mass (product not tested by Aistila. Information from restaurant studies). For chicken nuggets, it is around 15% and 25% for chicken kebab. The upcycled paste is then “hidden.”

SuperGround fish paste from upcycled fish bones

If the paste is used as a majority component in products, they often have a bit softer texture than fillet-based products. Taste and smell depend on the recipe, since the paste itself has quite a neutral flavour and odour.

But, of course, it still depends very much on the final product. There are very different kinds of nuggets and fish balls (i.e., mechanically separated meat (MSM), fillet-based, etc.).

FF: What are the main challenges in the application of SuperGround paste in food production?

Santtu: The main challenge was developing products made with over 90% SuperGround paste. The creation of something completely new is always slow, and it requires a lot of imagination. And what do people really want to buy?

We already have a few such products waiting for production.

FF: Are there any ongoing research or development projects related to SuperGround paste, particularly in terms of expanding its usage or improving its properties?

Santtu: Yes. There are numerous ongoing projects regarding product development and quality improvement. Continuous innovation is our core value at SuperGround.

FF: Do you believe that consumer acceptance will be a barrier? What insights did you gain from the consumer attitude studies regarding the purchase and consumption of meat products containing softened ground bones?

Santtu: I believe that consumer acceptance will not be a major barrier. Especially because SuperGround paste can be used in existing food products. A consumer does not have to change their eating behaviour, yet it can become more sustainable.

Our consumer attitude studies in Finland, Sweden, and Germany have provided us with insights that, if products are good, a large majority are ready to buy products with hard tissues. I’m confident that eating hard tissues from bone upcycling will become normal, as it happened with mechanically separated meat.

SuperGround fish bone paste improves texture

FF: What potential applications do you see for SuperGround paste beyond existing products, and how do you envision its role in future food innovations?

Santtu: SuperGround aims to contribute to the EU Green Deal by developing new sustainable and nutritional seafood with easy direct access to a wider population. We are also aligned with several UN sustainable development goals (SDGs). Our invention supports the sub-goals of “ensuring a sustainable food production system and ensuring access by all people to safe and nutritious food all year around” of SDG 2: Zero Hunger. We have a great number of new products and technologies coming up in the future. We will tell you more about it when we have progressed with those to a certain level.

FF: What is your business model? Do you plan to develop your own products with ground bones or work with manufacturers?

Santtu: We are currently exploring multiple avenues of market penetration and options for business models. To prove market demand and product proof of concepts, we have already done small-scale market tests ourselves, but our plan is to partner with industrial companies for industrial-scale production.

FF: When can we expect a product on the market?

Santtu: The first product is already on the market. Rainbow trout fishballs with 30% paste have been in numerous lunch restaurants here in Finland. More products will be launched soon.

SuperGround fish sticks

FF: What advice would you give to food manufacturers or individuals interested in incorporating SuperGround paste into their products, based on your findings and experiences?

Santtu: Be open for potential uses! We have had multiple cases where we have been thinking that SG paste might not suit a product, but after some collaboration, we found out that it actually does. Some of our best products were considered impossible before we tried them.

As Santtu points out, there’s no lack of information about the changes that need to be made in the food system. And it starts with our plates. But the biggest challenge is behavioural change. People have their own beliefs, and their own right to buy and consume the way they want. For food innovators like Santtu, if we want to have immediate changes, we have to improve the existing system. Improve what is served on the plate – in terms of taste and nutrition without compromising the health of the planet.

Find out more about the upcycling sector through our Food Data Navigator or contact us for a tailored consultancy. To learn more about the 2023 FoodTech 500 ranking and global FoodTech ecosystem insights, visit forwardfooding.com/foodtech500.

Are you an AgriFoodTech startup? Early Applications for the 2024 Edition of the FoodTech 500 is now OPEN.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]