FORWARD FOODING

THE BLOG

Yeastime: Making Fermentation Sustainable with Ultrasound Waves

Yeastime founders turned their homebrewing hobby into an innovative startup that reduces the fermentation process by 30%. Now, they are on a mission to apply their technology to boost sustainability in the food industry.

The origins of fermentation date back over 9,000 years. This process allowed early societies to preserve food, enhance flavors, and improve nutritional value. Today, fermentation has transcended traditional applications and entered the realm of biotechnology. Modern techniques are now utilized to produce a wide range of products, from food and beverages to pharmaceuticals and biofuels. One innovation in this space is Yeastime’s mechanical treatment technology, which uses ultrasound to improve the efficiency of the fermentation process.

We talked to Yeastime Co-founder and CEO Pierfrancesco Mazzolini about the beginnings of their innovative solution, the various potential applications for their technology, the goals they are trying to achieve, and the hurdles they hope to overcome. Yeastime is one of the finalists in the 2023 FoodTech 500.

This interview has been edited for clarity and concision.

Forward Fooding: Can you give us some background information on how Yeastime came into existence?

Pierfrancesco Mazzolini: Yeastime’s genesis was a convergence of diverse talents and deep friendships. Yeastime is an Italian startup established in early September 2021. We have developed and patented an innovative technology that leverages ultrasounds to help fermentation producers accelerate their fermentation process by up to 30% to become more sustainable and cost-effective.

In early 2021, my friend Federico Ortenzi, who has a background in industrial biotechnology, came to me with these literature papers about bioacoustics. Bioacoustics is a discipline that integrates physics and biology to explore and understand evolution by considering mechanical pressure as a stationary factor.

The literature found that living microorganisms like yeast, bacteria, microalgae, and fungi with instrumentation responded positively to certain types of frequencies and mechanical stimulations. Since we homebrew together in our garage, we decided to delve more into this topic more from economics and marketing points of view.

We checked the market to see if there were any technologies developing ultrasounds for bioprocess simulation or applying them to the canonical fermentation process. There wasn’t any technology doing it. And we said, imagine if we could apply a technology like this to Heineken or Perroni, and a reduction of fermentation time of even 1% could mean lots of benefits from both the economic point of view and the sustainability point of view.”

In early 2023, we participated in Dock3 The Startup Lab,

a program that permits people to present their ideas and find team players with multidisciplinary characteristics different from the one proposed. There, we met our third co-founder, Alessandro Contaldo, who has skills and knowledge in electrical engineering. During the four months of the program, we developed our first MVP, a small ultrasound generator that we applied to our homebrewing fermentation tank in our garage.

We ended up winning the incubation program, which granted us €10,000 and permitted us to establish the startup and collaborate with the University of Tor Vergata to gather and lay the foundations for what now is our patent.

Eventually, two other co-founders came in Luca Buccarello, who is a full-stack developer and has expertise in IoT, and Ulisse Castellano, who is now in charge of the sales and marketing area.

Our collective vision, nurtured by friendship and a shared commitment to innovation, propelled Yeastime from concept to reality. With each member bringing unique expertise to the table, we are poised to revolutionise the biotechnology landscape.

FF: Why did you start with homebrewing or beer?

Pierfrancesco:

We started with beer because we already had all the raw materials, the yeast, and the primary instruments to apply our technology. Also, from a market perspective, the brewing industry is a €600B market. It’s one of the biggest industries in fermented products, and beer itself is the third most consumed beverage in the world. So, from a market point of view, it made total sense to start from an already established industry that would never die. We also did some rounds of product market fit with brewers within our region. We immediately perceived that they needed our technology, which can be applied as a noninvasive solution that could increase the productivity of existing fermentation tanks.

So, that has given the validation and the push to keep developing in that segment; however, we’re not stopping there. We are a startup, and a startup, by principle, needs to maintain and nurture the research and development area. So, two and a half years ago, we started developing and laying the foundation around yeasts, specifically Saccharomyces cerevisiae, the principal strain for the beer brewing application. But we’re also testing our technology on other microorganisms that have a fermentation process at their base, such as Microalgae We are continuously testing and applying our technology on lab-scale bioreactors, starting from one liter to 30 liters.

FF: Can you describe “common” technologies in the industry that optimize the fermentation process and how your technology compares?

Pierfrancesco:

In the current market, many companies try to optimize the fermentation process. However, none focus on accelerating the process by acting on cellular metabolism.

We differ from the competition because we are introducing a non-invasive solution as a process optimization tool. It can meet efficiency parameters regarding fermentation time reduction and increase microbial productivity without minimally touching or altering the organoleptic properties of the fermented culture.

Our technology acts from the outside, and from a food safety point of view, that is a good thing because inserting a technology that would touch the products would require a lengthy process of food safety approvals and regulations before going to market.

FF: Assuming all conditions are great, what would be your roadmap for Yeastime?

Pierfrancesco: Our scalability goals are enclosed within two major strategies. One is a vertical strategy to scale up and the other one is a horizontal strategy.

The vertical strategy is to ensure and validate our technology in terms of volumes of fermentation tanks and bioreactors that can be reached. So we started, for example, on one litre and went all the way up to ten litres. Now, we are in the industrial scene, where we have tested our technology on 1600 litres.

The next goal for what regards the beer brewing industry is to test our technology on 3000 litres and 5000 litres by Q4 of 2024. Then, replicate this strategy on other microorganisms as well. For example, we have validated our technology on two different microalgae strains. Now, we are approaching what a vertical scale-up is. So we have validated on five litres and ten litres and now we’re going to move up over volumes with the intent to reach 100 litres.

We want to do the same with bacteria and funghi-based microorganisms. I say horizontal because there are different microorganisms and strains and vertical because of the bioreactor’s reach and volumes.

FF: How does it also compare in terms of costs or ease of use?

Pierfrancesco: We are unaware of the prices of other devices in this sector. However, what we have found to be the main unique selling point for our producers is that we are non-invasive. Thanks to the optimization that we bring, the producer also gets a high return on investment.

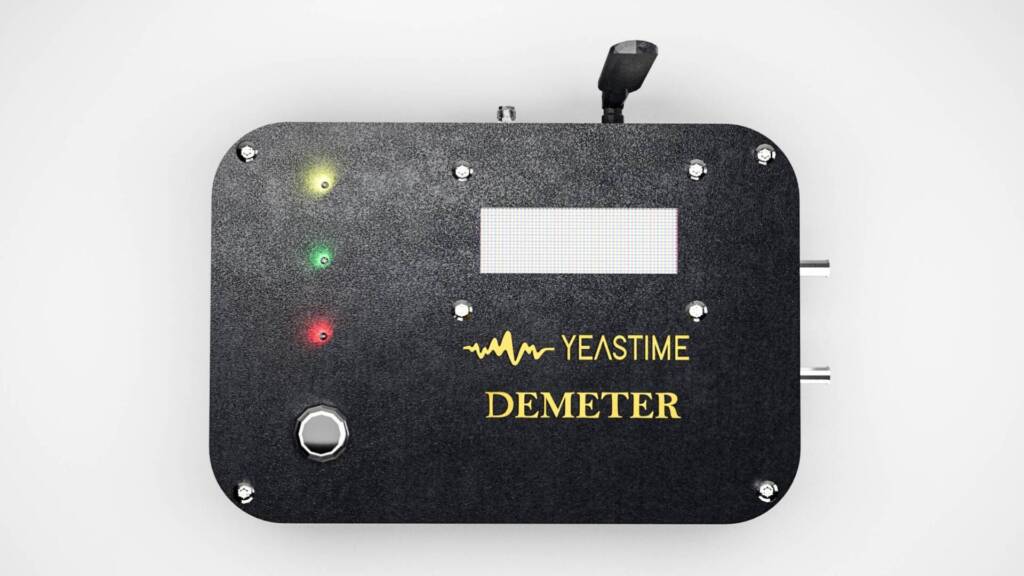

Yeastime Lab Scale

FF: You mentioned exploring other areas, like green algae. Will you also be exploring different kinds of fermentation, like precision fermentation and biomass fermentation, in the FoodTech scene?

Pierfrancesco: Yes, absolutely. Biomass increases yield when using our technology on yeast-based strains. So apart from Saccharomyces cerevisiae,. We’re also now testing on bacteria, which are widely used in the alternative protein industry on the FoodTech scene and the pharmaceutical industry. We are strongly dedicated to seeing and ensuring the potential of our technology on different microorganisms.

FF: What is the potential impact of this fermentation technology on the food industry?

Pierfrancesco: The fermentation technology developed by Yeastime has the potential to have a significant impact on the food industry in several ways:

- Faster Fermentation Process: The technology has been shown to reduce fermentation time by an average of 30% in brewing processes. This accelerated fermentation can increase production efficiency and speed up time to market for fermented food products.

- Increased Metabolism: The technology can increase cellular metabolism without altering pH or temperature, improving fermentation efficiency. This can result in higher yields of fermented products, enhancing productivity in food manufacturing.

- Diversification of Fermented Products: The technology is adaptable to various types of fermentations, including classical, alcoholic, heterolactic, and homolactic fermentations. This versatility allows for the production of a wide range of fermented food products, expanding the market’s offerings.

- Alternative Protein Production: The technology can be applied to the production of alternative proteins through precision fermentation, potentially increasing the efficiency of protein production from microorganisms like yeasts, fungi, bacteria, and microalgae. This can address the growing demand for sustainable protein sources in the food industry.

- Sustainable Production: The technology can contribute to sustainable food production practices by optimizing fermentation processes and increasing the availability of consumer goods. This includes the production of secondary metabolites of interest, such as antioxidants and fatty acid methyl esters for biofuel extraction.

Overall, Yeastime’s fermentation technology has the potential to revolutionize the food industry by improving production efficiency, product quality, and sustainability in the manufacturing of fermented food products.

FF: Would you mind sharing how your business has been funded up until now?

Pierfrancesco: Yeastime’s financial plan has been carefully structured to align the company’s vision and strategic scalability goals.

A key partner in Yeastime’s growth path is Big Idea Ventures, the most active investor in the world for what concerns the alternative protein and fermentation industry.

Yeastime Fermentator

FF: What’s the biggest challenge in your business?

Pierfrancesco: The biggest challenge in the biotechnology business, particularly for companies like Yeastime, may involve overcoming regulatory hurdles and ensuring compliance with industry standards. Developing innovative bioprocess solutions often requires navigating complex regulatory frameworks, obtaining necessary certifications, and meeting stringent quality control requirements. Additionally, establishing market credibility, building customer trust, and differentiating the product from competitors can pose significant challenges. It is crucial that we stay abreast of evolving regulations, maintain high standards of quality and safety, and effectively communicate the value of our solutions to address these challenges successfully.

FF: What’s your biggest need for now? Do you need funding or more collaborations?

Pierfrancesco: We are young and need funding to accelerate and meet our scalability goals. We are also in open talks with investors for our seed round. We’re seeking €1M, which we will allocate for the production of devices for the brewing industry, for hiring key resources in our team from biotechnology, physics, sales, and marketing, and to unlock our R&D potential to keep testing our technology on other microorganisms.

We also look forward to establishing partnerships within the community, not only from the commercial side but also from research and development. We would love to partner with startups at similar stages and combine our technologies.

To learn more about the 2023 FoodTech 500 ranking and global FoodTech ecosystem insights, visit forwardfooding.com/foodtech500.

Are you an AgriFoodTech startup? Early Applications for the 2024 Edition of the FoodTech 500 is now OPEN. The deadline for early bird application is July 31st.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]