FORWARD FOODING

THE BLOG

Ittinsect is transforming aquaculture feed with insect protein and agricultural byproducts

In the rapidly evolving world of aquaculture, sustainability is no longer just a buzzword—it’s a necessity. With the rising demand for fish and seafood, traditional fish meal production, which involves harvesting wild fish to create feed, has put immense pressure on our oceans, leading to overfishing and biodiversity imbalance.

Enter FoodTech 500 alum Ittinsect, a pioneering company led by founder Alessandro Romano, which is turning the tide with its innovative approach to fish feed. Ittinsect is developing a sustainable alternative to conventional fish meal by harnessing the power of insect protein and agricultural byproducts. This groundbreaking solution reduces the need for ocean fishing and cuts down on carbon emissions, offering a more environmentally friendly option for aquaculture.

In this exclusive interview, Alessandro shares the journey of Ittinsect, the challenges of scaling insect-based feeds, and his vision for a sustainable future in fish farming.

This interview has been edited for clarity and concision.

Forward Fooding: How would you explain your job to someone outside FoodTech/Agtech?

Alessandro Romano: We leverage the power of enzymes and microorganisms to create valuable nutrients from byproducts. What we do is replicate protein that generally comes from fish that is caught from the oceans. We replicate it through biotechnological processes that are applied to byproducts in waste from agriculture and insects so that we don’t need to catch fish for aquaculture feed anymore.

We create a protein similar to fish that is not intended for human consumption. Currently, most of the protein obtained from fish in the ocean is given to fish in aquaculture—in fish farms. We apply biotechnology to insects and agricultural byproducts to produce similar proteins that could replace fish meal. Our product helps decrease the need to fish from oceans for aquaculture feed.

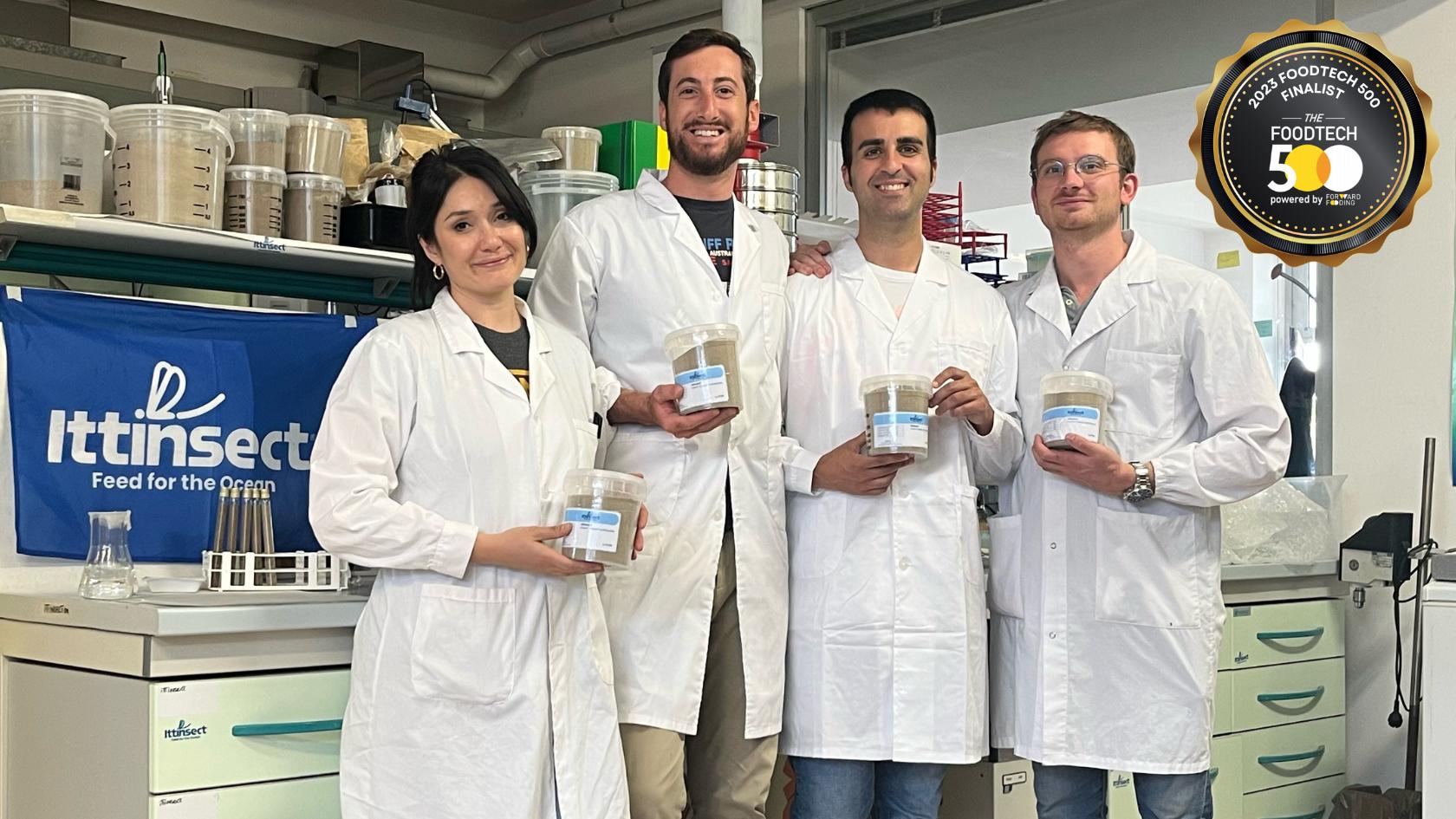

Ittinsect aquaculture feed

FF: How did it all start? Why did you choose to solve this particular problem?

Alessandro: As the founder of Ittinsect, my role was not to find the solution but to identify the problem. I’m very passionate about the ocean. I go sailing, fishing, surfing, etc. One day, I decided to connect to the ocean on a deeper level. So, I lived for more than a month sailing, sleeping on the beach, and only eating the fish I could catch.

During my dives, I realized how little fish is left in the ocean, as I witnessed a lot of commercial fishing activity around me. So, I decided to study what was going on. Why was there so much trawling going on, and why was there so little fish near the coasts? I then found out that a quarter of global fishing, which is more than 20 million tonnes of fish, doesn’t go into human food, but it gets ground and dried to become a protein meal as feed for fish farms. It’s a big paradox because farmed fish is the cleanest source of animal protein that we can get in terms of CO2 emissions. It’s very good to eat fish. But the bottleneck is in the feeds. So, I built a team around this problem to try and address it. We decided that we could make a protein that would replace fish meal one to one. Now, here we are with a fish meal replacement protein that is used in aquaculture. It’s been used in Italy, and we’re also starting to sell it abroad.

FF: Could you share any insights into the market demand for insect-based aquafeeds and how it has evolved over time?

Alessandro: The supply of insects towards the upper poultry sector is growing steadily, but not as fast as the insect farmers were expecting. In my opinion, one of the reasons is that insects are a very good source of protein, but they’re not optimized yet in terms of protein density to price ratio. There are still a lot of antinutritional factors in insects that need to be addressed, and insect farmers are working to address them through better insect genetics.

But, we believe that there is a faster and more effective way to improve insect proteins. We extract those proteins in the cleanest way from antinutritional factors. We then turn them into digestible proteins by cutting them into three amino acids that fish can better absorb.

We also process agricultural byproducts to extract the amino acids that were missing from natural insect meal, completing the amino acid profile to match the needs of a fish diet.

FF: But conventional fish meal does not have to go through that process. Are you providing a better solution and better food for the fish?

Alessandro: Conventional fish is not optimised. Fish is an ingredient mixed with other ingredients to be extruded into fish feed. So, the original fish meal is already a very good ingredient in terms of nutritional properties. It’s important for fish farmers today to include fish meals because it helps the fish grow healthy and fast and reduces mortality.

But the issue is, on the one hand, environmental because we are destroying the oceans to produce fish meal. On the other hand, it is economically less feasible now because there are so few fish out there that producing fish meals has become very expensive, and fish farmers can’t afford to buy feeds that include these ingredients anymore. So we solve both problems at once, making a larger availability of fish meal equivalent and keeping a stable production.

FF: How does Ittinsect collaborate with other stakeholders in the aquaculture and agriculture industries to promote innovation and sustainability?

Alessandro: Currently, we have 22 fish farmer clients. They choose Ittinsect-based feeds because of three main factors:

- Fish grow faster, reducing their production cycle

- Fish become healthier, resulting in less mortality

- Fish weight is improved as they build more muscle

Because of these reasons, fish farmers can make more margins when fish are sold to distributors.

We’re happy they buy our feeds because they are also much less impactful. So, we help them reduce their impact, as well as the impact of the agricultural value chain in general. By using our feeds in 2023, we produced 28,000 extra portions of fish for free. We also upcycled four full trucks of agricultural byproducts, reducing waste in landfills. Lastly, we protected three and a half million fish from being caught to become feed for fish farms.

FF: Did you do a sustainability report or LCA study to publish these findings?

Alessandro: We will publish our findings next week. But, we have not made a full life cycle assessment because our production process is still being optimized. So, it would be pointless to do a full life cycle assessment in a process that is changing- every quarter, it’s getting more efficient. But we have run an internal analysis of our products versus the sustainability reports of the main feed producers in the world.

FF: What regulatory frameworks or standards govern the production and use of insect-based ingredients in aquafeed, and how does Ittinsect navigate those?

Alessandro: The regulatory framework is opening up slowly for normal foods in general. Registering novel foods isn’t as fast as in other countries or continents. But I have to be honest, we have bypassed this problem for now because we outsource 100% of our production to companies that have all the certifications and authorizations so that we can quickly sell volumes without needing to comply with regulations ourselves as a company, even though our products do comply with all the regulations.

Obviously, we will need to adapt to regulations once we build a full-scale factory, but that will be in a few years, so we were not particularly concerned about that.

Regulatory approval for novel food and novel feed ingredients in the EU is never a matter of time and how keen you are. But it is good because it’s a barrier that not many can overtake. Having motivation and a structured team helps in this case. We are confident that when it is our turn to gain certification, we’ll get them successfully.

FF: What do you wish could change to make regulatory approval much faster?

Alessandro: It would be amazing to receive quick feedback once we apply, whether it will work or not, if some modifications are needed, etc. Instead, it takes many months to even get something back. And it’s normal because there are a lot of applications, especially for local proteins.

But startups work very fast. Time can make a startup die, even if it has a good product. So, public entities dealing with startups need to respond quickly because that could change a whole company and potentially the entire technology.

I also believe that regulators could push large corporations to innovate more. If a large corporation is forced to buy a product or technology, it will put more pressure on public bodies to approve it. Large corporations have the power of lobbying, and we don’t as startups.

FF: Are you talking to corporations to help you push for faster regulatory approval?

Alessandro: We have very good relationships with corporates that are market leaders in our segment. But again, they are not pressured to innovate as quickly as the world needs them to. If they are more pressured and innovate quicker, they will help technologies like ours go faster. If they want to adopt this technology, they will push for rules and regulations to be confirmed or applied more quickly.

FF: Have you encountered any challenges unique to insect farming for aquafeed?

Alessandro: The biggest challenge is keeping a high-performing, highly motivated, highly skilled team. The team is really the key to everything we do. We worked very hard to have the team that we have today, which is a very serious, generous team in terms of technical and business skills.

Everything we do is correct on paper, but the company has high and low periods in terms of scientific research, sales metrics, etc. But despite this, it’s always important that each team member is happy and doesn’t feel too much pressure. We need to be aligned with our mission to effectively contribute to our personal and professional mission.

FF: Looking ahead, what are your aspirations for Ittinsect in terms of growth, scalability, innovation, and impact on the aquafeed industry?

Alessandro: Our motto has always been market first. Unlike most biotech startups in the feed industry, we launched our product when the company was only one year old. We made very little from it, but it was enough to secure the first sales, attracting more sales and investors.

Our business runs on two parallel lines—the first is research and development. We improve our market fit every day by making products that always perform better and are less costly. In parallel, we have strong products that have already been validated in the market. These products help grow our customer base and keep improving our financials—although we’re still dependent on venture capital money. But growing at this pace, we should be breaking even by the end of 2025.

Between now and the end of 2025, we will have completed our market expansion in France and Spain for our feed products and commercialized our first stand-alone ingredient for Norwegian salmon.

FF: Would you continue taking investor money or prioritize profitability first?

Alessandro: Yes, indeed, as our goal is to grow big. So, we could be a stand-alone company by the end of 2025, but it will be a small stand-alone company. We would rather keep growing to a level that makes an actual impact because, in the commodities industry, you don’t make an impact by making thousands or even millions of tonnes of product. There are 20 million tonnes of fish out there that get caught and turned into feeds. We want to replace as much of it as possible, so we need to produce big.

FF: To achieve your goal, what do you ask of people in the AgriFood space?

Alessandro: To the stakeholders- the customers, consumers, the people who eat fish, they would be very happy to know that they are reducing their impact. I ask that we all spend a bit more on each part of the food chain to reduce our impact considerably, starting with our ingredients. Another thing I would ask consumers is to keep getting informed about where your products are coming from and try to understand how impactful you’re being because this helps the whole industry to evolve in the healthiest way.

To learn more about the 2023 FoodTech 500 ranking and global FoodTech ecosystem insights, visit forwardfooding.com/foodtech500.

Are you an AgriFoodTech startup? Early Applications for the 2024 Edition of the FoodTech 500 is now OPEN. The deadline for early bird application is July 31st.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]