FORWARD FOODING

THE BLOG

Can We Unbottle the Plastic Crisis?

To address the plastic crisis, the resurgence of reusable packaging systems offers a hopeful alternative. Transitioning from a linear, disposable economy to a circular model focused on durability and reuse can significantly reduce waste. However, this shift presents challenges, including the need for new materials, cleaning processes, and infrastructure. In our latest blog post, we delve into the challenges of adopting reusable systems, such as infrastructure needs, standardization, and cost issues. We also highlight the efforts of startups and emerging technologies working to overcome these challenges and the recent corporate initiatives that are bringing reusable technology into practice.

The Plastic Crisis

Plastic pollution has reached alarming levels, with key numbers illustrating the severity of the issue. Each year, over 300 million tons of plastic waste are produced globally, and only about 9% is recycled. The rest ends up in landfills, oceans, and natural environments, causing significant harm to wildlife and ecosystems. This pollution problem demands urgent action, not only from industries but also from consumers who are increasingly aware of their environmental impact and are demanding more sustainable products (88% of consumers in the U.S. and U.K. want brands to help them live more environmentally friendly lives).

Single-use plastics, primarily made from fossil fuel-based chemicals, are designed to be disposed of after just one use. According to the plastic pollution coalition, 40% of plastics are made for single-use purposes. These plastics are most commonly used for packaging and service ware, such as bags, bottles, wrappers, and straws. The environmental impact is staggering, with 1 million plastic bottles bought globally every minute and up to 5 trillion plastic bags used annually.

Single-use plastics are particularly challenging to recycle due to their small size and tendency to fall into recycling machinery crevices. As a result, many recycling centres do not accept them.

The Return of Reusables

The plastic crisis demands innovative solutions. One promising approach is the revival of reusable packaging systems. By shifting from our linear, disposable economy to a circular model that prioritizes durability and reuse, we can significantly reduce waste. However, transitioning to a widespread reusable system presents unique challenges.

The widespread use of single-use plastics is largely due to their low cost and convenience, despite their devastating environmental consequences. Current materials and infrastructure are ill-equipped for the challenges of reusable packaging systems. Overcoming the challenges of transitioning to reusable packaging requires a concerted effort to develop durable materials, establish efficient cleaning and refilling processes, and create accessible return points. We will expand on these aspects further down.

The concept of reusable packaging is not new. For generations, items like glass milk bottles and beer kegs have been successfully reused. Refill stations and deposit return systems have also demonstrated the viability of circular packaging models. These historical examples underscore the potential for a widespread shift towards reusables. As consumer awareness grows and technology advances, the future of reusable packaging is poised to scale rapidly. In the most ambitious scenario, the Ellen Macarthur Foundation estimated that reusable packaging could lower greenhouse gas emissions and water use by up to 70% compared with single-use plastics.

Corporate initiatives

Leading corporations are taking significant steps towards reusable packaging. For instance, Coca-Cola and PepsiCo set industry-leading targets in 2022 to deliver 25% and 20% reuse by 2030. Innovative solutions are driving progress toward these reuse targets; as seen with PepsiCo’s expanded its home-based refilling options through SodaStream.

In 2023, Unilever has joined forces with QYOS to establish refill stations for home care products in Jakarta, Indonesia. This initiative is expanding to include Unilever’s network of waste banks in the Greater Jakarta and East Java regions, offering convenient refill options to local communities.

In 2023, Nestlé has partnered with Circolution to pilot a reusable packaging system for Nesquik. Circolution provides standardized containers, handles logistics, and manages the return of these containers, while Nestlé focuses on product production.

Major chains like Starbucks, KFC, Dunkin’, Burger King, and Peet’s Coffee, have launched a city-wide reusable cup initiative in Petaluma, California. Starting August 5 2024, the three-month pilot will involve serving to-go drinks in specially designed purple reusable cups. Customers can return these cups at any participating store in Petaluma, where they will be sanitized and prepared for reuse.

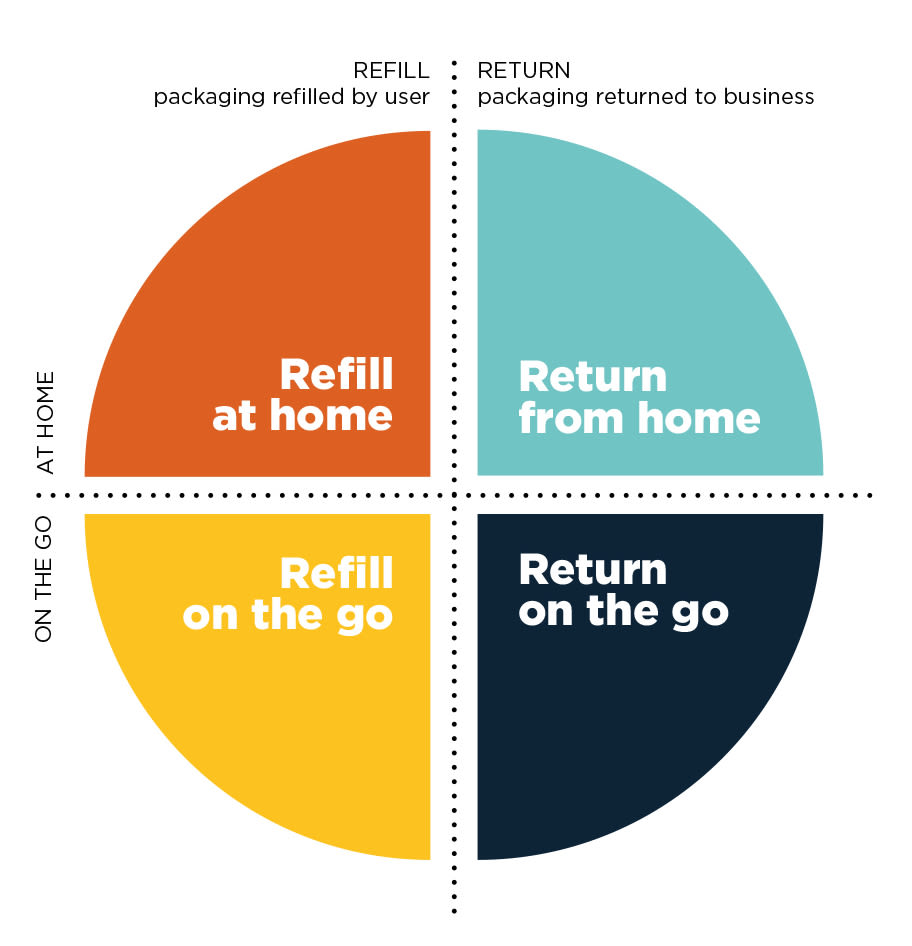

Reusable Packaging: Models

Reusable packaging can happen in four different ways:

- Refill at home. Users refill their reusable containers at home (for example, include using refillable pouches for household cleaners or durable glass jars for food items like grains and spices).

- Return from home. Packaging is collected from home by a pickup service (for example, by a logistics company).

- Refill on the go. Users refill their reusable containers away from home (for instance, at an in-store dispensing system).

- Return on the go. Users return the packaging to a store or drop-off point (for example, at a deposit-and-return machine).

Source: Ellen Macarthur Foundation

Reusable Packaging Examples and Innovators

Our FoodTech Data Navigator tracks 83 companies in the reusable packaging sector, which have raised €627.5 million since 2014. From 2021 to 2023, these companies recorded a 15% CAGR.

Reusable technologies are transforming how food is packaged, delivered, and tracked, offering sustainable alternatives to single-use packaging. Companies are developing reusable containers that can reduce waste in the food delivery industry and general take-out industry. Innovative apps are helping consumers participate by making it easier to track and return packaging. Advanced technologies are being integrated into packaging to provide greater transparency and traceability in the food supply chain. Logistics companies are creating solutions to ease the transition to reuse for both manufacturers and consumers, by creating modular and containerised technology (e.g. filling and washing lines to add to current hubs).

The rapid growth of this sector is underscored by the fact that 75% of companies have been founded since 2018.

Let’s take a look at some of the innovators in the space!

Companies Specialising in Logistics

Logistics are crucial for reusable packaging because they ensure efficient collection, cleaning, and redistribution of packaging materials. Typically, logistics companies operate in a B2B model and help streamline the reuse process by partnering with B2C companies.

Loop, managed by TerraCycle, creates a circular ecosystem for reusable items by collaborating with brands, retailers, and manufacturers. Present in 22 countries, Loop handles the reverse supply chain, collecting used packaging online or at return points, sorting, sanitizing, and returning packaging for refilling. They have collaborated with retail partners like Carrefour, Walmart, and Tesco, and individual brands such as Ariel, Evian, and Nutella for reusable scheme. In 2022, Loop teamed up with Burger King to test reusable packaging in the UK.

Reusable Scheme in London in Tesco’s. The range included 88 products from popular UK brands such as Persil, Fever-Tree, Carex, Tetley Tea, and BrewDog, along with 35 Tesco own-brand essentials like pasta, rice, oil, and sugar. Customers select prefilled reusable containers from the Loop fixture in-store, with no need to bring their own containers. A refundable deposit starting at £0.20 is charged at checkout and refunded via an app upon returning the packaging to a store collection point.

EcoSpirit has developed automated sanitization and filling stations (ecoPLANTS) for 4.5L containers (ecoTOTES) of liquid. EcoTote containers are designed for self-dispensing and can be used up to 150 times. EcoSpirits handles the collection and reverse logistics of its containers, ensuring the return to the EcoPlants for washing, sanitizing, and refilling. The company received a €9 million Series A funding round in May 2023, with investors including Pernod Ricard’s venture capital fund and Closed Loop Partners. They have partnered with various hospitality venues and have collaborated with Bacardi, Carnival Cruise Line, DIAGEO, Remy Cointreau, and Black Cow Vodka.

UK-based company Again provides an end-to-end solution for reusable packaging, collaborating on packaging design, cleaning, sanitizing, redistribution for refill, and data analysis for detailed reports on return rates, units reused, and CO2 savings. Their CleanCell technology is a micro-cleaning facility that sorts, cleans, de-labels, dries, and palletizes reusable packaging. In 2023, Again partnered with Abel & Cole, Milk and More, and smol. They also started a trial with Uber Eats in Central London in late 2023.

Dizzie is a return-and-reuse e-commerce platform that manages the filling, washing, and distribution of reusable containers for ambient foods from their central London “Reuse Hub.” Their primary focus is aiding retailers and brands in transitioning to reusable packaging. Dizzie partnered with Abel & Cole (since 2020) and recently with Waitrose, ASDA, Co-op, and Amazon. Future plans include expanding their reusable packaging line to include liquids, though specific details are yet to be disclosed.

Kadeya offers a closed-loop beverage vending machine that washes, sanitizes, and refills glass or stainless steel bottles. All bottles are digitally identifiable via QR codes, and a return bin is provided for used bottles. Kadeya introduced its system at a large construction site in the US and is now available for pre-order. In 2023, they were contracted to supply vending machines to two US Air Force bases to reduce single-use plastic.

Uzaje specializes in integrated waste management solutions, with a focus on cleaning and reusing a diverse range of containers: bottles, stainless steel containers, jars, dishes, cutlery, bowls, crates, and secondary packaging in stainless steel, glass, or durable plastic. In November 2023, Uzaje announced an €11 million funding round to support its expansion in France and Europe. They’ve also recently introduced Hygie, a tool to help businesses decide between internal or external washing options.

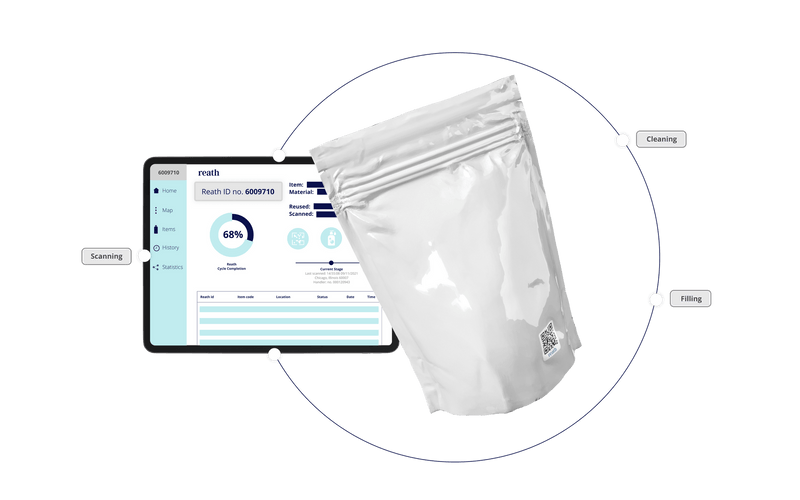

Reath.id is a software platform that provides machine-readable trackers, such as QR codes and NFC tags, for managing reusable packaging systems. Their innovative technology also includes an Open Data Standard, hosted on GitHub, which facilitates comprehensive traceability and encourages broader industry adoption. Reath has trialed their solutions with various returnable packaging companies and has gained recognition through winning the Bring It Back Fund from Hubbub and Starbucks, as well as being nominated for the Earthshot Prize 2023. They recently secured Seed round funding led by Techstart, with support from Elemental, Echo River Capital, and others. Their platform can generate performance data, including return rates, cost savings, and the number of single-use bottles avoided.

Companies Specialising in Direct-to-Consumer

For reusable packaging companies specializing in direct-to-consumer, the consumer journey is streamlined to make the transition to reusable options easier. Customers can easily return used packaging via pre-paid labels or drop-off points. Companies handle the cleaning and sanitization, ensuring packaging is safe and ready for reuse. Companies handle the cleaning and sanitization, ensuring packaging is safe and ready for reuse.

Modern Milkman is a doorstep grocery delivery service for milk, juice, eggs, butter, bread, fruit, and vegetables, using plastic-free packaging and reusable glass bottles. They use AI to map efficient delivery routes for delivering and collecting empty bottles, which are returned to producers for cleaning and refilling. In 2022, Modern Milkman raised £50 million in a Series C Funding round with investors like Insight Partners and ETF Partners. In May 2023, they partnered with Dizzie to launch the ‘The Refillables’ range, starting with breakfast essentials.

Algramo has developed vending machines that dispense household cleaning products using RFID-enabled bottles. In 2023, they were finalists in the Packaging Europe’s Sustainability Awards. They partnered with Lidl in 2022 to launch the UK’s first laundry detergent refill station using smart chip technology.

Fyllar provides a smart refill solution for cleaning products using refillable pouches with RFID-tagged smart caps to prevent spillage. They were finalists in the 2023 Packaging Europe’s Sustainability Awards. Fyllar partners with Lidl in the UK and Netherlands, Walmart in the USA, and brands like ECOVER in the Netherlands.

Key bottlenecks for Reusable Packaging

-

- Lack of Scale and Shared Infrastructure: The lack of scale and shared infrastructure poses significant challenges for the reusable packaging sector, with insufficient infrastructure for collection, sorting, cleaning, and transportation resulting in high costs.

- Insufficient Packaging Standardisation and Pooling: Additionally, the absence of packaging standardisation and pooling decreases efficiency in sorting, cleaning, and storing, while ineffective pooling leads to higher transport distances, emissions, and costs.

- Product Cost: Reusable packaging needs to be cost-competitive with single-use alternatives. Consumers should be incentivized through lower costs to return containers. For businesses, transitioning to reusable systems involves significant investments in machinery and infrastructure. Cost efficiency can be achieved through standardization and harmonization across the value chain, from production to retail. Economies of scale are essential to lower per-unit costs and achieve cost parity or savings.

- Product Safety: Packaging must maintain product safety, preserving food quality and minimizing waste. Reusable packaging should meet existing safety and hygiene standards. Key areas for higher adoption include nonperishable items with low barrier needs (e.g., dry goods, concentrates) and products requiring high insulation (e.g., home-delivered food). Ensuring that reusable solutions meet these requirements is critical for their success.

Conclusion

A new wave of startups is challenging the dominance of single-use plastics by reviving the age-old concept of refillable and reusable packaging. By offering practical, convenient solutions for both consumers and businesses, these companies are demonstrating that a future without mountains of plastic waste is not only possible but already within reach.

Enabling consumers to adopt reusable packaging at scale is tricky for a whole range of reasons, but the growth in the number of startups working to overcome those hurdles, and the growing interest from major corporations, shows that the foundations are in place. Government policies can help clear the way to build on those foundations, from bans on certain types of single-use packaging (e.g. Europe Ban on Single-Use Plastic for cups, food and beverage containers ) to tax incentives for going reusable (for instance, the San Francisco Mayor and SF Environment Department launched a new program to help restaurants switch from single-use disposables to reusable items. The initiative offers financial aid, free technical support, and a $500 incentive for purchasing reusable food ware).

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]