FORWARD FOODING

THE BLOG

The Predictive Recipe: AI-Powered Innovation in Food Formulation and Production

In today’s rapidly evolving food landscape, companies face mounting pressure to innovate faster, operate more efficiently, and meet increasingly personalised consumer demands. Climate change, volatile supply chains, cost constraints, and shifting health priorities are forcing both startups and established manufacturers to rethink how food is developed and produced.

Predictive Modelling in Food: Why It Matters Now

McKinsey estimates that AI could unlock up to $500 billion in annual global value, particularly by doubling the speed of innovation across industries. Within food manufacturing, predictive analytics is projected to save up to $127 million by 2030 through reduced waste and smarter production planning. In parallel with the food sector’s growing need for speed and precision, AI and large language models (LLMs) are unlocking entirely new research frontiers. Models like GPT-4, PaLM, and LLaMA are already reshaping how we approach data-rich, high-complexity domains. They can perform well even in few-shot or zero-shot learning contexts, and their ability to simplify scientific knowledge and deliver personalised, site-specific recommendations is being explored in agriculture and food science alike (Tzachor et al., 2023, Tian et al., 2024).

Predictive modeling is emerging as a game-changing tool in food formulation and manufacturing. Powered by artificial intelligence (AI) and machine learning (ML), predictive models can simulate ingredient interactions, optimize production processes, and forecast consumer preferences—all before a product hits the shelves.Once confined to pharmaceutical or aerospace applications, these tools are now being integrated into the food innovation pipeline, helping teams cut R&D time, lower costs, and make smarter, data-driven decisions.

According to our FoodTech Data Navigator, as of today, we count 780+ AgriFoodTech companies leveraging AI & Machine learning. They have raised $3.856B in 2022, $1.887B in 2024, and $653M in 2025. Key sectors include AgTech (354 companies), Food Safety & Traceability (94), Consumer Apps (90), Kitchen & Restaurant Tech (78), Food Processing (76), and Next-Gen Food & Drinks (17).

For now, our focus will be specifically on Food Processing, Formulation, and Next-Gen Food & Drinks—areas where predictive AI models drive innovation in ingredient optimization, functional formulation, and scalable production.

This article explores how predictive modelling is transforming the way food is formulated and produced. We’ll look at why this technology is gaining traction now, how it’s being applied across the value chain, and what challenges and opportunities lie ahead.

What Are Predictive Models in Food Formulation?

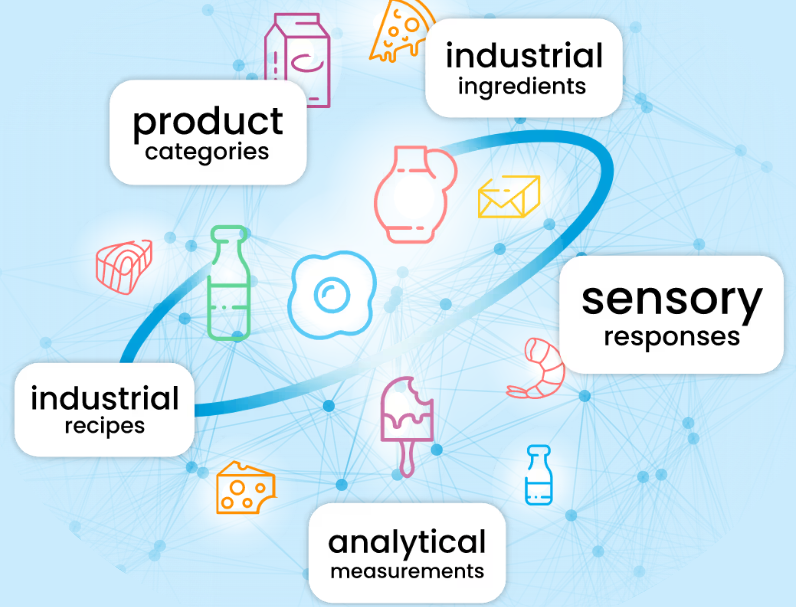

At their core, predictive models are AI- or machine learning-powered tools that use existing data to forecast future outcomes. In food formulation, that means predicting how different ingredients will interact, how a recipe will perform in production, or how a consumer might perceive flavour or texture—all without running endless physical trials in the lab.

Think of it as a smart simulation engine: instead of formulating by trial and error, food scientists can now run thousands of virtual experiments using historical datasets, molecular information, and sensory data to find the best-performing combinations. Let’s break that down with a few food-specific examples:

- Flavour interaction modelling: Predictive tools can anticipate how flavours will blend, clash, or enhance one another based on their chemical structures—helping create more appealing taste profiles or mimic traditional flavours in plant-based formats.

- Texture optimization: By analyzing the physical properties of ingredients (like viscosity, elasticity, or mouthfeel), predictive models can suggest changes that improve texture—whether it’s making a dairy-free cheese melt like the real thing or ensuring a protein bar stays soft over time.

- Predictive food microbiology in fermentation that uses AI models to describe and predict the growth, survival, or inactivation of microbes in food systems.

- Ingredient substitution: Want to remove allergens, reduce sugar, or make something vegan? Predictive models help identify functionally equivalent substitutes that maintain product performance—without sacrificing taste or stability.

Behind the scenes, these models often draw from fields like chemoinformatics, food material science, and sensory analysis. They connect molecular-level insights to real-world product behaviour, effectively bridging science and creativity. The result? Faster formulation cycles, fewer failed prototypes, and smarter, more scalable innovation.

From the Lab to the Factory Floor: Applications in Production

The transition from lab to the factory floor in formulation and production is significantly enhanced by the integration of predictive models, which play a crucial role in anticipating process performance, including fermentation behaviour, shelf-life, and yield. These models enable manufacturers to optimize energy use and minimize waste, which is increasingly vital in today’s sustainability-conscious market. Furthermore, they facilitate personalized production planning, allowing for small-batch customization and agile supply chain adjustments.

Case Studies: Predictive Models in Action

Predictive modeling is no longer confined to theory or high-tech labs—it’s driving real-world transformation across every stage of food innovation. Well-known pioneers like NotCo have showcased how AI can revolutionize ingredient design and product formulation, setting a benchmark for others in the field. Below, we explore how companies in our ecosystem are using AI/ML to accelerate product development, scale biomanufacturing, and unlock novel ingredients. Each example reflects a key activity cluster in the predictive FoodTech landscape.

Brightseed: AI-powered Discovery of Bioactives

Cluster: Discovery & Analytics Platforms

Tech: Forager AI Platform

Brightseed’s proprietary Forager AI scans molecular data across thousands of plants to identify bioactive compounds with functional health benefits—compounds that would take years to isolate using traditional methods. In a recent collaboration with Danone North America, Brightseed mapped out gut health-supportive molecules in chicory root, dramatically accelerating ingredient validation and regulatory compliance. This AI-driven shortcut is shrinking discovery timelines from years to months, while opening new commercial pathways in functional foods and nutraceuticals.

Bioactive fiber from upcycled hemp (Source: Brightseed)

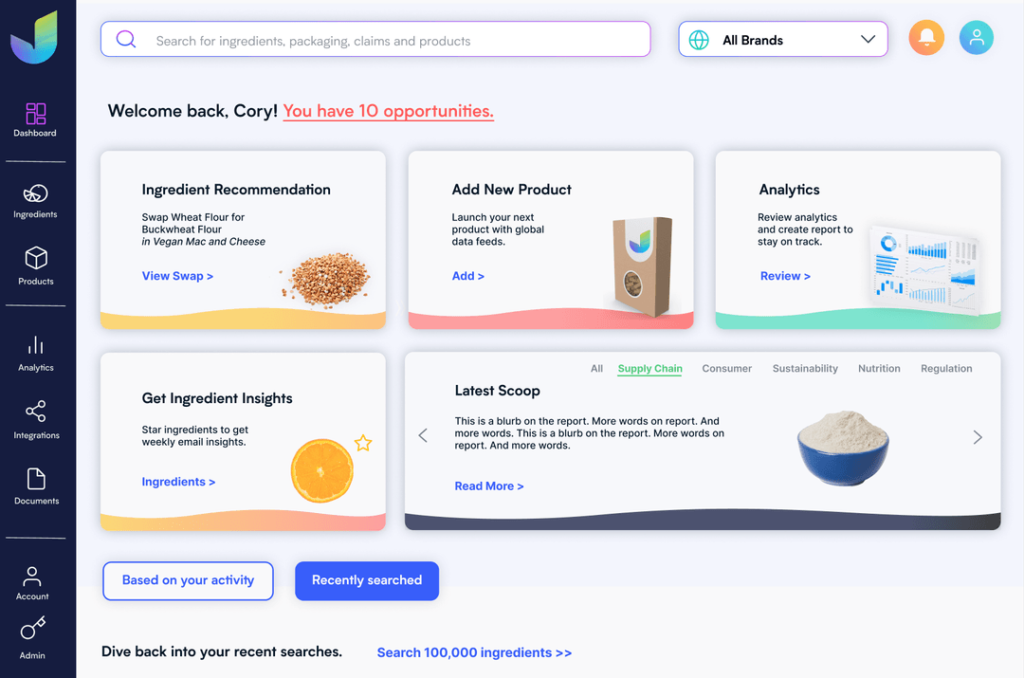

Journey Foods: Predictive Ingredient Optimization for CPGs

Cluster: Discovery & Analytics Platforms

Tech: Ingredient Intelligence Platform

Journey Foods partners with CPG companies to redesign legacy products using AI. Their platform evaluates over 1 billion ingredient combinations based on nutrient density, allergenicity, cost, and sustainability impact. By applying predictive models to product reformulation, they’ve helped brands cut R&D cycles by up to 60% while ensuring taste parity and supply chain scalability. It’s a game-changer for startups and corporates looking to reformulate quickly in response to regulatory shifts or changing consumer preferences.

Ingredient Discovery, Formulation Optimizer, Supply Chain Monitoring Platform (Source: Journey Foods)

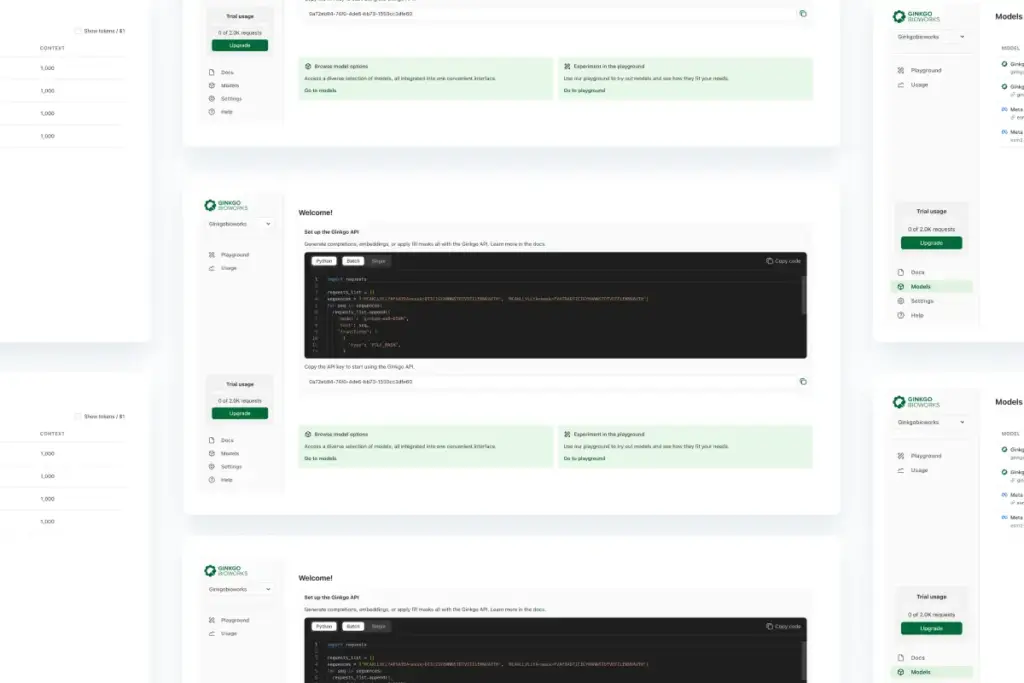

Ginkgo Bioworks: Predictive Cell Programming at Scale

Cluster: Protein Engineering & Synthetic Biology

Tech: Cell Engineering & ML Modeling

Ginkgo Bioworks integrates AI modeling with synthetic biology to engineer custom microbes for everything from meat analogs to dairy proteins. Their platform simulates genetic edits and metabolic outputs before physical testing, allowing precision iteration in silico. Through predictive optimization, Ginkgo has reduced development time for some engineered strains from 18 months to under 6 months, enabling faster go-to-market timelines for partners like Motif FoodWorks and ADM in the alt-protein space.

The platform includes end-to-end fermentation optimization and scale-up expertise from high-throughput screening through pilot-scale production and downstream processing. (Source: Ginkgo Bioworks)

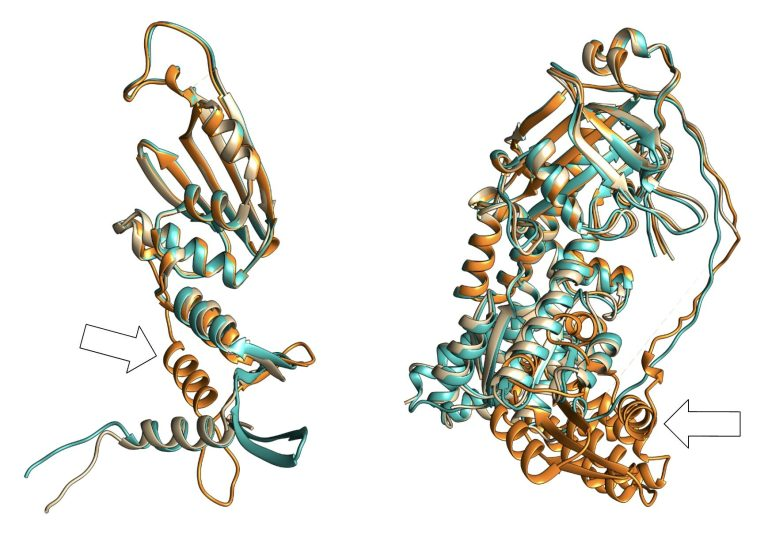

Basecamp Research: Mapping Proteins from Biodiversity

Cluster: Protein Engineering & Discovery

Tech: Biodiversity Graph AI + Cloud Biobank

Basecamp Research is building the most diverse protein database on Earth by collecting DNA samples from extreme ecosystems and feeding them into a graph-based AI model. This approach allows the prediction of structure-function relationships of novel enzymes without wet-lab testing. Their models have helped partners identify rare proteins for improved digestibility and stability in plant-based foods, providing a computational edge in designing next-generation alternative proteins and functional ingredients.

BaseFold: A breakthrough in structure prediction of large, complex protein structures (Source: Basecamp Research)

CureCraft: Digital Twins in Fermentation Process Design

Cluster: Protein Engineering & Discovery

Tech: Smart Bioprocess Modeling Platform

CureCraft is redefining how novel proteins and enzymes are designed. Using proprietary AI models, they simulate, predict, and optimize protein function before a single experiment is run. Their in silico platform accelerates the discovery of high-performance biomolecules for applications ranging from therapeutics to precision fermentation. In early-stage collaborations, partners have reported up to a 25% improvement in functional protein yield and reduced development timelines—unlocking faster, cheaper paths to scale in areas like cultivated meat and industrial biocatalysis.

Design process in fermentation (Source: CureCraft)

Hoow Foods: Computational Reformulation for Healthier Foods

Cluster: Food Technology & Nutrition Solutions

Tech: RE-GENESYS™ Predictive Reformulation Engine

Hoow Foods is at the forefront of AI-powered food formulation, using its proprietary RE-GENESYS™ platform to reinvent high-calorie, nutrient-poor products into healthier, regulatory-compliant alternatives—without compromising on taste or texture. The system simulates ingredient interactions at the molecular level, applying algorithms that factor in flavor chemistry, nutrient bioavailability, glycemic load, and local consumer preferences. Their approach represents a new breed of formulation science: not just “healthier by design,” but healthier by prediction—powered by a digital twin of the food matrix itself. This is especially relevant as markets like Southeast Asia and the Middle East push for products that meet both nutritional targets and cultural taste expectations.

A unique patent-pending, in-house proprietary deep-tech to power the development of best-in-class functional ingredients and food-reformulation capabilities. (Source: Hoow Foods)

AKA Foods: Accelerating Plant-Based Innovation with AI

Cluster: Food Technology & Nutrition Solutions

Tech: Proprietary STIR engine + Google Cloud / Vertex AI

AKA Foods uses AI to optimize plant-based product development through its STIR engine, which models taste, texture, nutrition, and regulations in a unified “food syntax.”

In one case, it helped a global CPG reduce R&D time for a plant-based cheese from 12 months to a few cycles, cutting onboarding costs by 90% and identifying top-performing recipes in days, thanks to integration with Google Cloud and Vertex AI.

AKA’s dynamic and secure expert AI algorithms are trained with millions of data points in our food labs and utilize proprietary food syntax and data structures. (Source: AKA Foods)

Challenges and What’s Next

While predictive models are unlocking new frontiers, scaling them in the real world still comes with hurdles.

The biggest challenge? Data quality and access. Many food companies sit on troves of data—often unstructured, siloed, or simply underutilized. Integrating AI into legacy R&D and manufacturing systems also takes time and cross-functional alignment. This space thrives at the intersection of food science, data science, and engineering—fields that don’t always speak the same language.

A concrete example: NotCo built its proprietary AI platform “Giuseppe” by training it on massive datasets combining molecular structures, ingredient matrices, and sensory profiles—essentially turning messy, fragmented food data into actionable formulations. Their ability to bridge data silos and extract insights across disciplines has been key to their success in replicating animal-based products with plant-based ingredients.

But change is accelerating and the companies that learn to treat data as a product, not just a byproduct, are leading the way.

The Takeaway: Prediction as a Superpower

Predictive modelling isn’t just hype. It’s already cutting costs, compressing timelines, and enabling food innovation at scale. The companies embracing it today are designing better products, faster. Those who wait may find themselves left behind.

For corporates and investors:

Book a demo of the Food Data Navigator or contact us for tailored consulting.

For startups:

Apply to join the FDN, engage with our community, attend our next event, and follow us on LinkedIn or subscribe to the newsletter. Let’s build the future of food together.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Written by: Giuseppe Monaco

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]