FORWARD FOODING

THE BLOG

How Food Structuring Technologies Enhance Performance and Nutrient Delivery

The conversation around functional foods is entering a new phase. The focus is shifting from what ingredients we use and how we formulate them to how nutrients are physically arranged, combined, and delivered within a food product.

This refers to the microscopic architecture of a food product, known as its food structure, which includes how fats, proteins, fibers, and other components are organized and interact. This can impact how well nutrients are absorbed by the body (bioavailability), the shelf life of a product, and its mouthfeel.

As food companies strive to meet the growing demand for plant-based, functional, and clean-label options, structuring technologies such as emulsions, gels, foams, and encapsulation are becoming increasingly powerful tools. From replacing unhealthy fats with healthy oils to transforming upcycled ingredients into tasty, nutrient-rich snacks, the way food is prepared is quickly becoming just as important as what we put into it.

This article examines how food structuring technologies are transforming the design of functional foods, shortening R&D timelines, and opening new opportunities for sustainable innovation.

Structuring in Food Tech: Why It Matters Now

As of 2025, the global functional food market is expected to surpass $400 billion, driven by health awareness, preventive nutrition, and personalized diets (Fortune Business Insights). Yet, many health-boosting ingredients such as polyphenols, probiotics, omega-3s, and certain plant proteins are unstable, poorly absorbed, or organoleptically challenging.

McKinsey’s State of Grocery Retail Europe 2025 notes that 45% of Gen Z shoppers, the highest among all cohorts, aim to eat healthier by putting functional, nutrient-rich foods at the forefront of innovation. Structuring technologies address the challenge by protecting sensitive ingredients, extending shelf life without refrigeration, and reducing additive use, which helps manufacturers maintain quality and functionality despite cost pressures or supply volatility.

What Are Structuring Technologies in Food, and Why Are They Critical Now?

Structuring technologies go beyond texture. They maximize bioavailability, clean-label functionality, shelf life, scalability, and consumer acceptance. It’s like reprogramming food at the micro and nano level, creating emulsions, foams, gels, and fat systems with targeted nutritional or sensory roles. Key domains shaping functional food manufacturing include:

- Microencapsulation & Controlled-Release

- Oleogelation & Lipid Structuring

- 3D Food Printing & Spatial Nutrition Design

Microencapsulation & Controlled-Release Systems

Microencapsulation is a key tool in functional food innovation that protects sensitive ingredients like probiotics, vitamins, enzymes, and polyphenols from oxygen, heat, light, or pH changes.

Applications include (Rokkam, et al, 2024):

- Spray drying – for powdered formats of heat-sensitive compounds (e.g., vitamin C, curcumin)

- Coacervation – uses pH or ionic changes to form biopolymer shells

- Liposomes & nanoemulsions – phospholipid or oil-based systems that boost absorption of fat-soluble actives

Oleogelation & Lipid Structuring

Oleogelation tackles the challenge of replacing saturated and trans fats without losing mouthfeel, structure, or stability. Using natural gelators (e.g., waxes, fatty alcohols, monoglycerides), liquid vegetable oils are transformed into structured gels that mimic solid fats.

Applications include (Le, Qianyu, et al. 2025):

- Delivering lipophilic nutrients (omega-3s, curcumin, vitamin E) in shelf-stable formats

- Enhancing creaminess in plant-based spreads, dairy alternatives, and bakery fillings

- Replacing hydrogenated oils without sacrificing taste or texture

3D Food Printing & Spatial Design of Nutrition

3D food printing, once a novelty, is now gaining traction in areas requiring precision, customization, and patient-centric nutrition. By layering edible pastes, gels, or emulsions, it creates structures impossible with traditional manufacturing.

Applications include (Cotabarren et al, 2023):

- Personalized nutrition for elderly or dysphagic populations

- Nutrient-controlled foods for clinical use or athletes

- Playful, interactive formats for children’s nutrition or premium markets

Other Structuring Techniques Worth Watching

A number of complementary technologies are helping round out the structuring toolkit:

- Cryogelation: leverages freezing to create soft, porous gels ideal for encapsulating delicate nutrients or building aerated textures. (Priyadharshini, S. R., et al. 2025).

- Extrusion and advanced texturisation: by applying controlled heat, pressure, and shear forces, ingredients such as plant proteins or fiber-rich upcycled materials can be transformed into fibrous, porous, or crunchy structures. (Lazou and Andriana, 2024).

- Foaming and aeration: critical for designing low-density, high-volume foods with improved mouthfeel and nutrient dispersion (e.g., whipped protein mousses) (Hashemi, Behnaz, et al. 2025).

- Hydrocolloid networks: polymers like pectin, carrageenan, and xanthan gum allow precise control over viscosity, gelation, and digestion dynamics. (Gao, Yanlei, Ru Liu, and Hongshan Liang, 2024).

Structuring Technologies in Numbers: Insights from the FoodTech Data Navigator

Although still relatively under the radar, structuring technologies in food—those that actively shape how nutrients are delivered, perceived, and metabolized—are quietly gaining ground. Forward Fooding’s FoodTech Data Navigator tracks over 280 companies in this niche, spanning microencapsulation, functional delivery systems, fat structuring, oleogelation, 3D food structuring, and additive manufacturing. Together, they’ve raised $2.4B+ since 2015, growing at a 7.4% CAGR from 2019–2024. Still a small cluster within AgriFoodTech, their precision and versatility position them as quiet disruptors—well-placed to meet the rising demand for personalized, functional, and sustainable nutrition.

Companies Innovating in Food Structuring Technologies

As these nutrient delivery trends gain traction, a wave of pioneering startups is bringing them to life through cutting-edge structuring technologies. From microencapsulation and oleogelation to 3D structuring and extrusion, these companies are rethinking how nutrients are protected, released, and experienced within food systems. Notably, all of these startups are featured on the FoodNavigator platform, highlighting their relevance, market traction, and role in shaping the next generation of functional foods.

Microencapsulation & Functional Delivery Systems

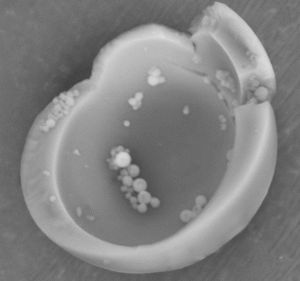

Calyxia: Unique Microencapsulation Technology (UMT)

UMT is a B2B company specializing in proprietary encapsulation platforms for food, nutraceutical, and pharmaceutical applications. They tailor microcapsule formulations to improve bioavailability, taste masking, shelf life, and controlled release. Their technology uses lipid, polymer, or hybrid materials to stabilize volatile ingredients and enable targeted release in the digestive tract—bridging formulation science with scalable manufacturing.

Non-Porous microcapsules: ingredients are fully protected and contained in non-porous microcapsules for optimal performance.

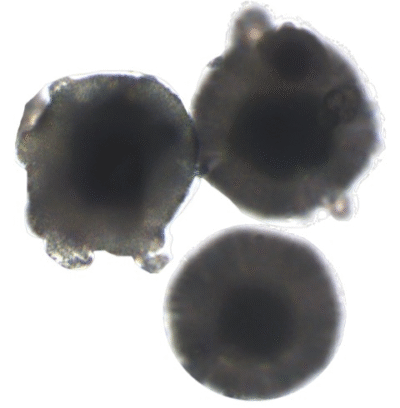

Mello

Mello is a wellness-focused foodtech company creating functional ingredients and supplements for mental clarity, mood, and recovery. Combining neuroscience with advanced formulation, they deliver active compounds without compromising taste or efficacy. Their microencapsulation technology protects nootropics and adaptogens from degradation and bitterness, boosting absorption and bioavailability while keeping clean sensory profiles.

Magnification of 3 x TrueCore-shell particles. Note ‘black shadow’ at centre – the active ingredient is isolated and protected in the center of the microbead.

Fat Structuring & Oleogelation

Perfat

Perfat engineers structured lipid systems that mimic the mouthfeel and functionality of saturated and trans fats—without the health risks. Ideal for bakery, confectionery, and plant-based meats, their solutions support clean-label, heart-healthy reformulations. Using oleogelation, they turn liquid unsaturated oils into solid-like structures with natural agents (e.g., waxes, proteins), delivering healthier fat profiles with appealing sensory qualities.

Cubiq Foods

Cubiq Foods, a Spanish startup, is revolutionizing fats for plant-based and conventional foods. They create structured fats—plant-based oleogels, hybrid smart fats, and cultivated fat cells—that enhance flavor, mouthfeel, and nutrition while replacing animal or hydrogenated fats sustainably and at scale. Their technology combines oleogelation with cellular agriculture to deliver next-gen fat systems tailored for texture, taste, and nutrition.

3D Structuring & Additive Manufacturing

Revo Foods

Revo Foods, an Austrian startup, leads in alt-seafood with premium plant-based fish like smoked salmon and fillets. They aim to ease marine ecosystem pressure by delivering realistic seafood alternatives that meet texture, taste, and nutrition standards. Their technology merges extrusion with precision 3D printing to align plant proteins into muscle-like, fibrous structures mimicking real fish.

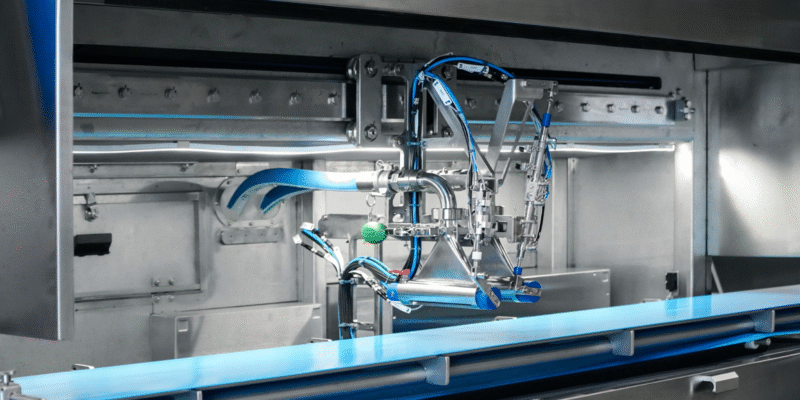

Cocuus

Cocuus is a Spanish deep-tech company developing 3D bioprinting and laser-structuring platforms for industrial-scale production of structured plant-based, cultivated, and hybrid meats like bacon, foie gras, and marbled steaks. They focus on scalable, modular, automated hardware. Their technology combines 3D laser printing with volumetric biostructuring for high-throughput, multi-textured foods with programmable design.

Novameat

Novameat, based in Barcelona, pioneers 3D printing of whole-cut plant-based meat. Unlike burger-style analogues, they recreate fibrous, muscle-like structures mimicking animal tissue, targeting foodservice and premium markets. Their technology uses bioinspired 3D micro-extrusion to align plant proteins, replicating the mouthfeel of beef or pork muscles.

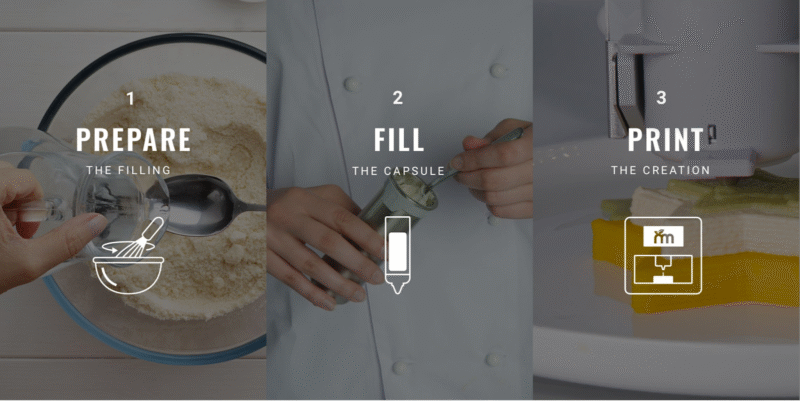

Natural Machines

Natural Machines, based in Barcelona, created Foodini—one of the first commercial 3D food printers. Targeting kitchens, hospitals, and innovation labs, Foodini enables custom, nutrient-controlled, and visually appealing foods. The company envisions personalized nutrition becoming mainstream in healthcare and hospitality. Their extrusion-based 3D printing shapes real food pastes with multiple ingredient cartridges for tailored recipes.

What’s Next: The Future of Nutrient Delivery in FoodTech

As food becomes more functional, personalized, and sustainable, structuring technologies are moving center stage, not just for form or texture but as the hidden engine behind performance and nutrient delivery.

AI-driven structuring is emerging, where predictive models meet food material science to design tailored, adaptive systems. Shiru and Journey Foods use data-driven platforms to identify functional ingredients and build smart nutrient matrices.

Smart delivery matrices, co-developed with ingredient suppliers, allow plug-and-play functionality without overhauling production. NutriLeads and Brightseed lead in bioactive discovery platforms for precision delivery.

Functional ingredient platforms that develop pre-structured solutions for outcomes like immunity or gut health are also rising. Mikuna leverages regenerative lupin protein to create bioavailable formats targeting energy, satiety, and gut health.

Collagen alternatives are gaining traction, with Geltor and Triton Algae Innovations engineering animal-free, highly bioavailable analogs through fermentation and algae, optimized for absorption and sustainability.

Structure is now a strategic lever to differentiate, scale, and deliver on the promises of modern food innovation, making how you deliver nutrients as important as what you deliver.

Ready to help shape the next generation of structuring technologies?

For Corporates and Investors, book a demo of the Food Data Navigator or learn more about our tailored Consultancy and Scouting Services.

For Startups, apply to the Food Data Navigator, join our community, and come meet us at our next event.

About the Writer

Giuseppe Monaco is a Food Science student focused on sustainable food systems innovation. Beyond his academic pursuits, Giuseppe volunteers with organizations addressing the social and nutritional aspects of food security. He is deeply committed to understanding agri-food policies and their role in creating a more sustainable food future.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]