FORWARD FOODING

THE BLOG

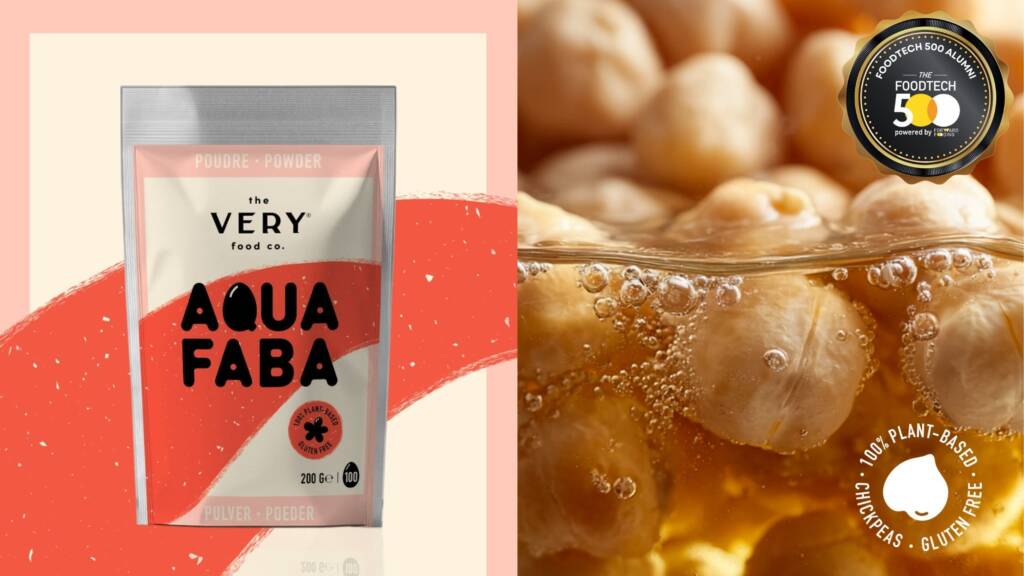

The VERY Food Co. Launches Industrial Aquafaba Powder to Replace Eggs

Image courtesy of The VERY Food Co.

The global egg market has been facing chronic price volatility, recurring health crises, and severe supply chain disruptions. For food manufacturers, this instability is a critical challenge. French food biotechnology company and FoodTech 500 Alumni, The VERY Food Co., is stepping up to solve it, and today they’ve announced a major move: the launch of VERY AQUAFABA POWDER, a clean-label, allergen-free powder version of their egg white alternative, specifically designed for the food industry.

Founded in 2022, The VERY Food Co. was born from a mission to reduce the food system’s structural dependency on animal-based ingredients. Co-founder and CEO Arnaud Delacour was deeply moved by the 2019 IPCC Special Report, which highlighted that livestock uses over 75% of the world’s agricultural land while providing only 18% of calories per consumer. The company’s goal is to enable a large-scale shift to plant-based ingredients without disruption, offering solutions that perform the same technological functions—foaming, emulsifying, texturizing—as their animal-based counterparts.

After a successful 2024 launch of its liquid aquafaba, which gained a solid foothold in foodservice across eight countries, The VERY Food Co. is now scaling up. The new powder format is lightweight, stable, and has a long shelf life, making it ideal for large-scale industrial use by reducing logistical footprints and allowing for precise dosage.

We asked the CEO, Arnaud Delacour, to discuss the strategy behind the launch, the lessons learned from the market, and his vision for a post-animal-based-egg-white future.

Arnau Delacour, Co-founder & CEO of The VERY Food Co.

This interview has been edited for clarity and concision.

Forward Fooding: The plant-based space has seen numerous egg replacer startups struggle or fail—particularly those using novel proteins or fermentation. You chose aquafaba, a more “mundane” chickpea byproduct. What lesson from those failures influenced your decision to standardize an existing resource rather than engineer something entirely new, and how does that affect your capital efficiency?

Arnaud Delacour: We’ve seen a wave of startups trying to reinvent the egg with complex formulations or precision fermentation. Technologically impressive, but commercially heavy. The key lesson for us was that functionality already exists in nature — you don’t always need to engineer something new to get results.

Aquafaba was already validated by chefs and home cooks. We weren’t starting from a hypothesis but from proof of use. That allowed us to build a supply chain instead of a lab. It’s far more capital-efficient: we optimize a natural resource rather than inventing one, and we focus our investment on process reliability, not protein design. In short, we’re betting on industrial pragmatism, not scientific novelty.

We often admire deep-tech breakthroughs, but food systems don’t reward novelty — they reward reliability. A new molecule can take a decade to reach the market, with regulatory hurdles and consumer skepticism along the way. Our approach was to take something simple and natural — chickpea cooking water — and apply science and process control to make it consistently functional. That’s where the real innovation lies: transforming a kitchen byproduct into a professional, predictable ingredient ready for industrial use.

Image courtesy of The VERY Food Co.

This pragmatic approach is reflected in one of the key lessons he’s learned: “Don’t burn the money you don’t have or cannot recoup with a realistic business plan.” By focusing on perfecting a known ingredient, the company has built a more resilient and capital-efficient model.

From Bartenders to Bakers: A Phased Go-to-Market

The move from a liquid product for foodservice to a powder for industry wasn’t just a format change; it was a deliberate strategic phase. Chefs provided invaluable insights into how hydration, sugar, and acidity influence foaming and stability, as well as the behavior of subtle flavor notes in desserts and cocktails. This feedback directly shaped the formulation of the powder, especially its solubility and concentration, ensuring it would perform consistently in larger-scale processes.

Forward Fooding: You launched liquid in 2024 and powder in 2025. Why did you need the foodservice liquid phase before going to industrial powder? What specific learnings from bartenders and pastry chefs informed the powder formulation? And were there customers asking for powder before you were ready to launch it?

Image courtesy of The VERY Food Co.

Arnaud Delacour: It wasn’t a planned sequence so much as a natural progression. We launched VERY AQUAFABA because chefs and bartenders were already using the liquid from canned chickpeas — they just needed a clean, consistent, ready-to-use version. The liquid format answered that immediate need and allowed us to validate the ingredient’s performance in real kitchens.

Once we had that proof of use, we started sharing samples with bakeries and manufacturers. That’s when we realized the format itself was limiting. Some worked with liquid egg whites, but many preferred powders for reasons of stability, storage, and dosing in production. That feedback made it clear that if we wanted aquafaba to reach the next level — beyond foodservice and into industry — we had to rethink the format, not the ingredient.

Forward Fooding: You’ve proven foodservice. Now you’re targeting industrial manufacturers with powder. Walk us through your industrial adoption playbook: Are you starting with specific applications (baked goods, plant-based products, etc.)? Are you targeting mid-size manufacturers before going after the giants? What does a typical pilot-to-full adoption timeline look like?

Arnaud Delacour: Our focus is on what we call semi-industrial users — the space between artisan bakeries and large-scale industrial groups. France alone has around 30,000 bakeries, including independent shops and consolidated chains. At the other end of the spectrum, a few hundred large industrial players dominate mass-scale production. The real opportunity sits in between: regional manufacturers and bakery networks that combine craft with scale.

That’s both where we start and where we intend to stay focused. These operators are technically skilled, flexible enough to integrate a new ingredient quickly, and large enough to make adoption meaningful. Big industrial manufacturers will likely come later, but they move slowly and require long R&D commitments. Our goal isn’t to spend years co-developing ingredients for a handful of conglomerates — it’s to build a business with agile partners who can move fast.

Image courtesy of The VERY Food Co.

We’re beginning with applications where aquafaba naturally excels: aerated and baked products such as meringues, mousses, sponge bases, and whipped toppings. A typical adoption cycle takes a few months, from initial trials to semi-industrial runs, and once it’s validated, integration tends to move quickly because aquafaba fits easily into existing recipes and processes.

France is our reference market because it’s the one we know best — a dense and diverse ecosystem that lets us demonstrate traction quickly. But our commercial ambition is much broader. We already distribute the liquid version in the UK, DACH, BENELUX, Australia, and Canada, so we know there’s pull beyond France. The goal is to use France as a proof point and scale from there, building a truly European — and eventually global — platform for plant-based egg alternatives.

Behind the “Drop-In” Promise and the Unglamorous Bottleneck

Aquafaba is one of the most studied natural foaming and binding agents. While it doesn’t mimic eggs molecule-for-molecule, it can perform reliably in production once its behavior is understood at a lab scale. The VERY Food Co. positions VERY AQUAFABA as a true drop-in replacement for egg whites. But as any food scientist knows, reality can be complex. Arnaud shares that The VERY Food Co.’s role is to facilitate a smooth transition by providing clarity and predictability, rather than promising a magic swap.

Forward Fooding: You position VERY AQUAFABA as a true drop-in replacement for egg whites. But in practice, how much reformulation or process adjustment is actually happening behind the scenes? Where does the “drop-in” promise hold perfectly, and where do your technical support teams have to get creative? What does this tell you about the next version of the product?

Arnaud Delacour: In practice, every ingredient change affects a process — even switching egg suppliers can alter texture or yield. Aquafaba is no exception. It works very well, but it has its own parameters that need to be understood.

That’s exactly why we’re focusing first on semi-industrial users. These bakers and pastry makers combine volume with craftsmanship: they can adjust hydration, mixing, or baking conditions as they learn how aquafaba behaves. Once it’s dialed in, the results are consistent and reproducible.

Image courtesy of The VERY Food Co.

Forward Fooding: What was the unglamorous, technical bottleneck you had to solve before this new product launch? The one thing that if you hadn’t cracked it, none of the rest would matter?

Arnaud Delacour: The biggest challenge was drying. Turning liquid aquafaba into a stable, soluble powder without losing functionality is more complex than it sounds. The proteins and fibers responsible for foaming and binding are heat-sensitive. If you dry too hard, you lose activity; too gently, and the product isn’t stable.

We spent months adjusting pre-concentration, temperature, and particle size to protect those properties while ensuring shelf life and flowability. It’s not glamorous work, but it’s what makes the powder reliable and scalable — and that reliability is what really opens the door to industrial use.

That learning now shapes our next R&D steps. We’re exploring more energy-efficient drying techniques that preserve performance even better while reducing cost and environmental impact. It’s incremental progress, but in food tech, those small optimizations are what make or break a category.

Forward Fooding: It’s 2035, and The VERY Food Co. has achieved its vision. What’s the headline you’d be most proud of?

Arnaud Delacour: “The VERY Food Co. made eggs optional.”

That’s the headline I’d like to read. Not that we eliminated eggs, but that we made it possible for the food industry to rely less on them — to choose plant-based options without compromise.

If, by 2035, aquafaba or its next-generation versions have become a standard ingredient across bakeries and food manufacturers, it means we’ve helped change the default of how food is made. That quiet shift — from dependence to choice — is the real impact we’re after.

And beyond the ingredient itself, it’s about creating a more resilient food system. If we can make the same foods people love — macarons, meringues, cakes — with fewer animals involved and less waste, that’s progress you can feel. It’s not about erasing tradition, but updating it for the next generation of chefs, manufacturers, and consumers.

The VERY Food Co. Team

An animal-free egg future

Their ambition is clear. Delacour explained that the company’s milestone for the next 12 months is to make aquafaba the foremost egg alternative and to lead the category in Europe, seeking to ensure that, “If it’s aquafaba, it’s VERY.”

This vision is backed by a powerful impact metric: for the same functionality, their solution generates over 90% less emissions than egg whites.

With this strategic launch, they are one major step closer to making that headline a reality.

FoodTech founders, ready to join the ranks of industry leaders? APPLY NOW to the 2025 FoodTech 500! Read all about what’s new and how startups, scale-ups, and ecosystem players can benefit from it.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]