FORWARD FOODING

THE BLOG

Air + Microbes = Food? How gas fermentation is set to revolutionize food production

History was made when Solar Foods announced the launch of the world’s first commercial-scale facility for making food out of thin air. Gas fermentation, more commonly referred to as ‘air protein’, is picking up steam. What may sound like building castles in the air is science-backed and presents a strong solution to produce food more sustainably.

Gas fermentation is having its moment. With the launch of Factory 01, Finland-based company Solar Foods can produce 160 tons of Solein® protein annually. Solein® is a microbial protein or a single-cell protein (SCP) or what is often referred to as air protein, produced in specially designed bioreactors using gas fermentation.

Gas fermentation companies leverage the abundant gases in the air such as carbon dioxide, hydrogen, oxygen, or even methane. It may seem outrageous at first, but remember how life in the universe first came to be? Out of thin air and a big bang. But the science exists. In fact, the foundational concept of generating protein from CO2, electricity, and water originates from research conducted by NASA in the 1960s.

We are merely witnessing the dawn of a paradigm shift in food production. Other players in the sector use gas fermentation to produce fats, pigments, animal feed, and alcohol. The application of the technology also extends to different industries that impact the planet such as fashion, fuel including sustainable aviation fuel, and energy.

“Bacterial biomass produced by gas fermentation is likely to take off in every sector of the food industry replacing unsustainable and poorly functional ingredients.” (Source)

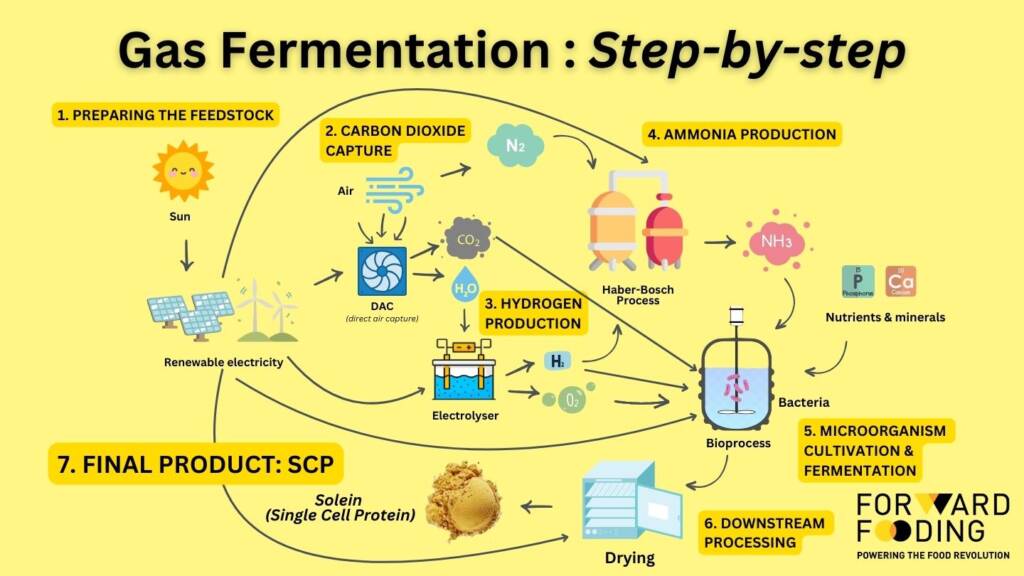

The Step-by-Step of Gas Fermentation

Production of protein from air such as Solein® involves microbial fermentation process, CO2 and electricity. Here’s a beginner’s guide:

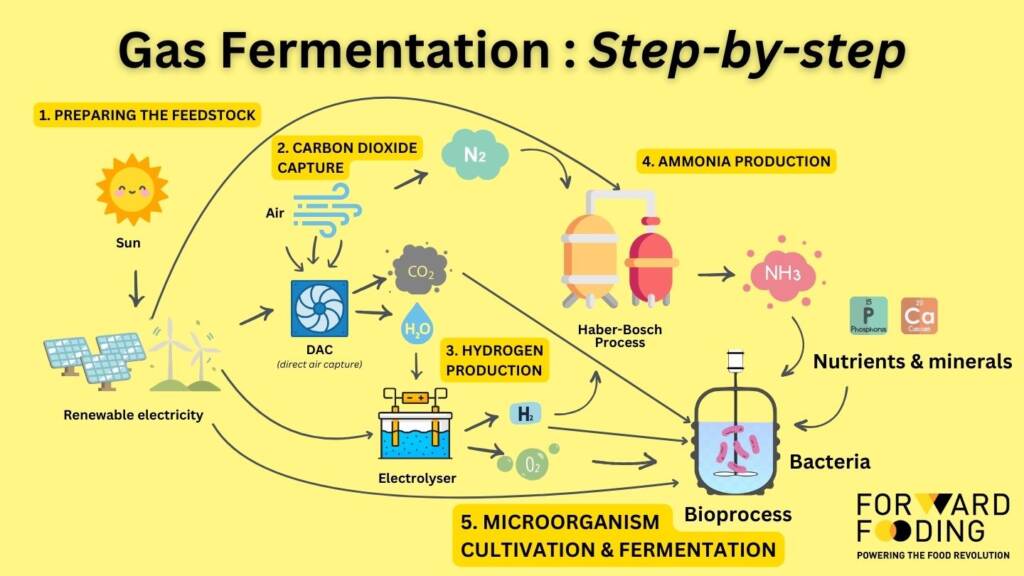

1. Feedstock Preparation

The key ingredients to produce air proteins include bacteria, electricity, and of course, air. The entire production process relies on renewable electricity, ensuring sustainability and minimising greenhouse gas emissions.

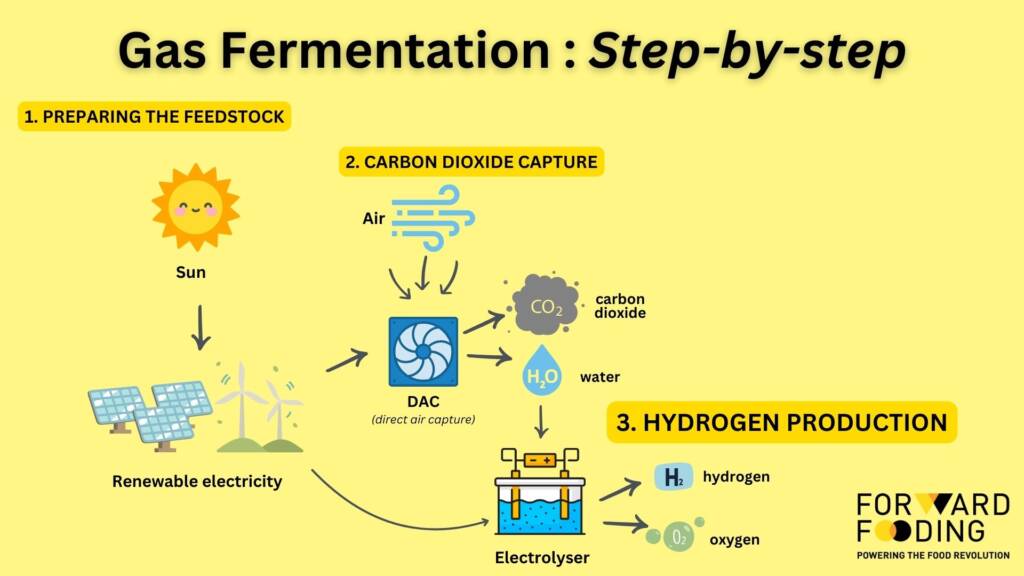

2. Carbon Dioxide Capture

CO2, essential for microbial growth, is acquired through direct air capture (DAC) technology or by capturing gases from industrial sources emitting CO2. Water is also captured from the air to be converted into hydrogen.

3. Hydrolysis

Electrolysis of water on-site yields high-purity hydrogen (>99%) and oxygen. These gases serve as essential components for the subsequent steps and are produced using renewable electricity.

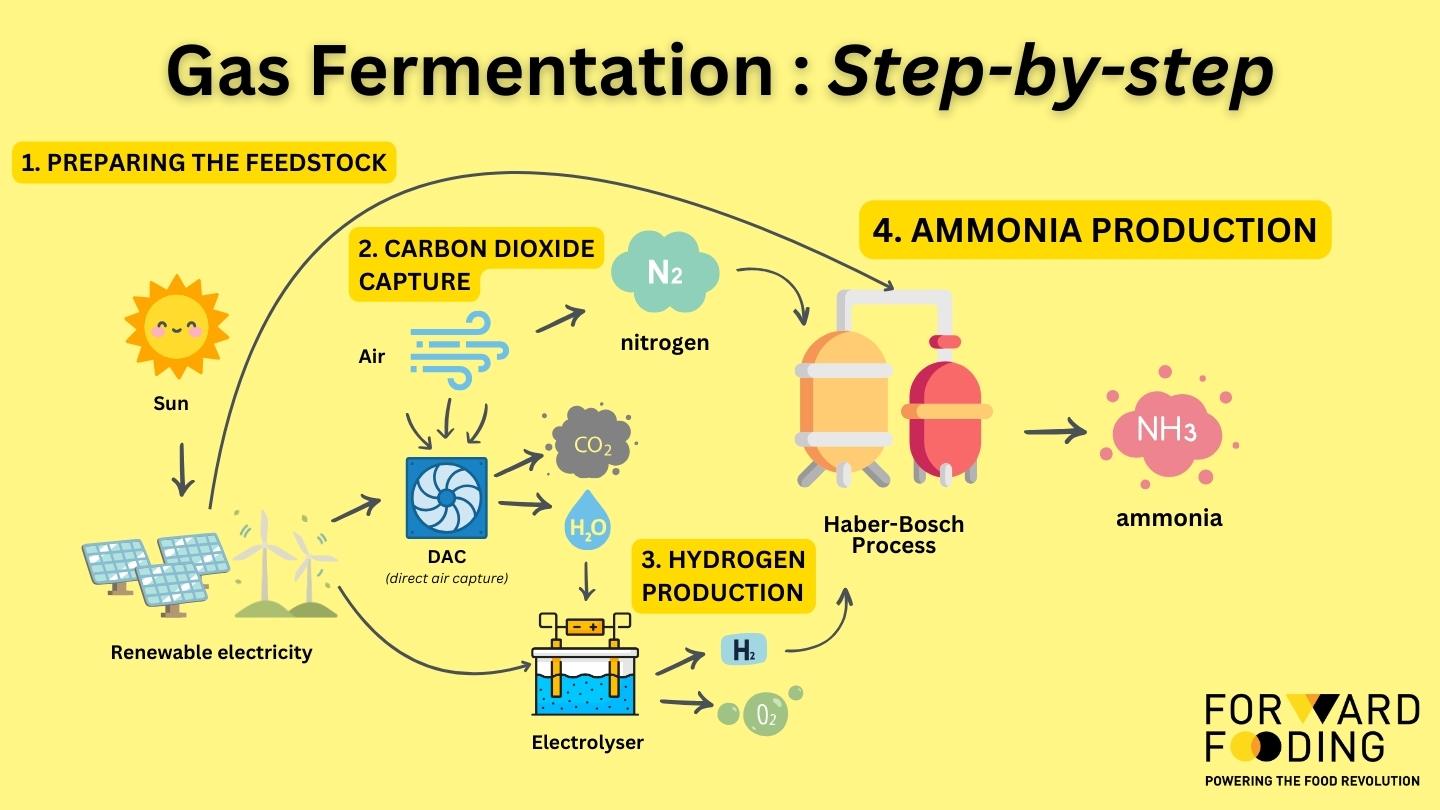

4. Ammonia Production

Nitrogen essential for bacterial protein synthesis can be supplied either as ammonia (NH3) or directly as nitrogen gas (N2), as certain autotrophic/ heterotrophic bacteria are capable of atmospheric nitrogen fixation. The synthesis of NH3 from H2 and N2 via the Haber-Bosch process ranks among the most energy-intensive procedures, demanding extreme temperatures and pressures (approximately 500°C and 20MPa). Moreover, it serves as a significant source of carbon dioxide emissions, as the energy for H2 production is typically derived from natural gas, coal, or oil. In the production of Solein, a portion of the sustainably-generated H2 can be allocated to ammonia synthesis, thus ensuring the overall process remains carbon-neutral.

5. Microorganism Cultivation & Fermentation

The process employs a microorganism cultivated in specialized bioreactors. This microorganism, a hydrogen-oxidizing bacteria, thrives in controlled conditions akin to those used in the production of baker’s yeast or lactic acid bacteria. Within the bioreactor, the bacteria utilize hydrogen as an energy source and CO2 as a carbon source to synthesize biomass. This innovative process operates independently of sunlight.

6. Downstream Processing

Post-cultivation, the bacterial biomass undergoes downstream processing to enhance safety, technological quality, and nutritional value. This includes drying the biomass into a powder form.

7. Final Product (SCP)

The resulting product, Solein, is a finely powdered substance containing approximately 65% protein. It undergoes further processing and formulation to create various food products.

Applications

Gas fermentation offers a range of innovative applications that could transform the food industry. Here are some key applications:

- Sustainable Protein Production: Gas fermentation uses a proprietary process to convert carbon dioxide from the air into protein, offering a highly sustainable alternative to traditional protein sources. This technology has the potential to address food security and environmental sustainability challenges by reducing the reliance on land, water, and energy-intensive protein sources.

- Nutritional Supplements: Gas fermentation can create high-protein nutritional supplements, providing a convenient and sustainable source of protein for athletes, vegetarians, and individuals with dietary restrictions. These supplements can be incorporated into shakes, bars, and other food products.

- Meat Alternatives: Gas fermentation can be applied to produce meat alternatives using a proprietary probiotic production process that produces air-based protein with an amino acid profile comparable to animal-based protein. This protein can be used to create meat substitutes like steaks, scallops, and other products typically derived from animals.

- Animal Feed: Gas fermentation can also be used as a sustainable source of protein in animal feed, reducing the environmental impact of livestock farming. This application has the potential to transform the agricultural industry by providing a more sustainable and efficient protein source for livestock.

Gas Fermentation and Air Protein Companies

Our FoodTech Data Navigator database currently counts 25 startups and scale-ups specialising in air protein and gas fermentation worldwide, which have raised a total of €521.8M over time.

- Air Co. (United States) – Specializes in creating consumer and industrial products from carbon dioxide

- Aircohol (Finland) – Specialises in producing drinkable alcohol from air, specifically from CO2 captured from fermentation

- Air Protein (United States) – Develops protein-enriched food made from CO2

- Arkeon (Austria) – Specializes in capturing CO2 emissions from industries and transforming them into organic food

- Calidris Bio (Belgium) – Transforms unique substrates into biomass with a high protein content, excellent feed for livestock, aquaculture, and pets.

- Calysta (USA) – Creates proteins for fish and livestock feed, pet food, and food ingredients via a patented fermentation platform

- Circe Bioscience (USA) – Makes products from carbon dioxide, water, and electricity starting with fats

- Circe (Austria) – Uses a patented “combined process” that utilises waste gasses, even capturing CO₂ to fuel innovative sustainable products such as food, feed and packaging

- Deep Branch (United Kingdom) – Focuses on using clean and renewable carbon and energy sources to create ingredients for a more sustainable food system

- Green On (Sweden) – Creates saturated fat from carbon dioxide, water, and electricity

- Hydrocow (Finland) – Engineers a microbe that converts CO2 and hydrogen into beta-lactoglobulin, a major constituent of milk

- Industrial Microbes (United States) – Specializes in designing and constructing microbes to produce chemicals with improved quality, reduced costs, and lower carbon emissions

- Ingrediome (Israel) – Develops recombinant animal matrix proteins made from carbon dioxide to make alternative meat and seafood

- Jooules (New Zealand) – Creates climate-positive proteins including food, feed, and pet food, from carbon dioxide

- Kiverdi (United States) – Uses NASA-inspired technology to transform carbon dioxide into bio-based products

- Novo Nutrients (United States) – aims to convert waste CO2 into valuable proteins and additives for food and feed

- Number8 (Australia) – harnesses carbon-hungry microbes that feed on greenhouse gasses and convert them into valuable animal feeds

- Savor (United States) – produces high-quality, healthy, and affordable fats and oils without negative climate impact

- Solar Foods (Finland) – its game-changing protein, Solein, is produced from air – CO2, water, nitrogen – and electricity

- Synergia Biotech (Canada) – specializes in using a community of microbes to remove CO2 from the atmosphere and produce a natural, vibrant blue pigment called phycocyanin

- UCDI (Japan) – Utilizes carbon dioxide and hydrogen to create organic compounds

- Unibio (Denmark) – Converts natural gas into a highly concentrated protein

Key Themes and Crucial Discussion Points

- Gas fermentation, despite relying on a 60-year-old technology, remains an emerging industry. With several startups and scale-ups worldwide concentrating on air protein and gas fermentation technologies, there’s increasing interest and investment flowing into this field.

- Gas fermentation ticks most of the sustainability checkboxes: 95% less water and 90% less land compared to traditional meat production, and doesn’t require fossil-fuel-derived fertilizers. Previous reports demonstrate that SCPs including those produced from gas fermentation use water and nitrogen resources far more efficiently than crops.

- Gas fermentation decouples from intensive resource dependence the way conventional agriculture does. This leads to a method of food production that can potentially reduce emissions and preserve the environment while making it possible to produce food in areas that are deemed impossible to farm, such as arid places or in the harsh Northern conditions of Finland all year round.

- Gas fermentation requires renewable energy sources to ensure sustainability throughout the production process. In a study, researchers noted that while the common assumption is that solar energy conversion efficiency is around 20%, it’s actually lower at the utility scale at around 5%. However, new ways to turn power into food in the form of SCPs offer hope for better efficiency. Advanced solar tech could soon make solar power even better, pushing efficiency beyond what we currently see. Following Moore’s Law, solar photovoltaic technologies benefitted from the significant drop in cost, allowing increased adoption, and is expected to continue in this trajectory.

- In a study comparing the efficiency of nutritional production of SCP via renewable energy sources, specifically photovoltaics, versus SCP from beets and soybean production, one hectare could supply the protein requirement for more than 500 people or 15 tons of protein per year.

- Production of protein through gas fermentation is significantly faster than raising livestock. It only takes hours while ‘livestock needs two years to go from suckling to sirloin.’

- Economies of scale are critical. This makes Factory 01 a crucial step not only for Solar Foods but also for the industry. As Solar Foods’ Founder, Pasi Vainikka, pointed out, “Someone needs to be first and create the market.”

- Consumer acceptance is a key concern for SCP, as it may face scepticism due to unfamiliarity, taste preferences, cultural factors, or perceptions compared to traditional protein sources.

- Consistent protocols for identifying and analyzing SCPs are vital to safeguard the safety of food and feed items. While EFSA has set up a committee to set guidelines for algae, unified standards are needed for all SCPs. CEO and Co-founder of Deep Branch, Peter Rowe, pointed out in 2023 the importance of having a “sufficiently unified voice from the industry” to impact adoption and regulatory approval. Solar Foods gained regulatory approval in Singapore in 2022 and is in the process of getting EU approval hopefully by 2025.

- Gas fermentation companies such as Solar Foods capture carbon dioxide using direct air capture technologies. DAC and other carbon capture methods are hailed as climate crisis solutions. Despite the potential advantages of DAC, there are also uncertainties. Experts warn that while they help cut emissions, they can’t replace urgent large-scale reductions needed to limit global heating to 1.5C and avert severe climate change impacts. Scientists argue that implementing carbon dioxide removal (CDR) technologies like DAC is ineffective until society has drastically reduced its polluting activities.

- In terms of economic and environmental viability, only a few thorough techno-economic assessments (TEA) and LCAs were done for DAC and there’s a notable discrepancy in DAC’s economic viability due to the absence of standardized methods, assumptions, and benchmarks. A recent article by the Environmental Forum shared several points on the inherent inefficiencies of current DAC technologies.

Learn more about our Taxonomy in our Activity Spotlight for Next-Gen Food and Drinks. Explore how gas fermentation such as air protein is utilised by companies in transforming the industry.

Forward Fooding is the world’s first collaborative platform for the Food & Beverage industry via FoodTech Data Intelligence and Corporate-Startup Collaboration – Learn more about our Consultancy and Scouting Services and our Startup Network.

Follow us

Sponsored Articles

9 July 2025

Forward Fooding celebrates the selection of 12 pioneering startups for the inaugural pladis Accelerator Programme. From water lily popcorn to sugar-converting enzymes, these innovations represent the future of snacking, addressing obesity, sustainability, and personalized nutrition through cutting-edge food technology.

21 March 2025

Tim Ingmire, VP of Global Innovation & Technology at pladis, discusses how the snacking giant is supporting early-stage startups in foodtech, health, and sustainability through their accelerator program. Learn about their focus on personalized nutrition, functional foods, and future ingredients to bring innovative, delicious products to consumers worldwide.

8 February 2024

Future Food-Tech returns to San Francisco on March 21-22 Over 1,700 food-tech leaders, from CPG brands, retailers, ingredient providers, [...]

1 February 2023

The 4th edition of FoodTech 500 is taking off and we are excited to partner with NEOM for the third consecutive year to support the best international AgriFoodTech entrepreneurs.

10 February 2022

One of the elements we enjoy the most here at Forward Fooding about working with AgriFoodTech startups is being [...]